CHAPTER 16 Case Study of a High-Tech Product Manufacturer

Semiconductor wafer fabrication is very competitive. Companies compete on cost, quality, and delivery time to market. In the age of digital information, a large amount of data (e.g., process data, equipment data, and lots of historical data) has been automatically or semiautomatically collected, recorded, and accumulated for monitoring the process, diagnosing faults, and managing the manufacturing process. Decision makers may potentially use the information buried in the raw data to assist their decisions through data mining for possibly identifying the specific patterns of the data.

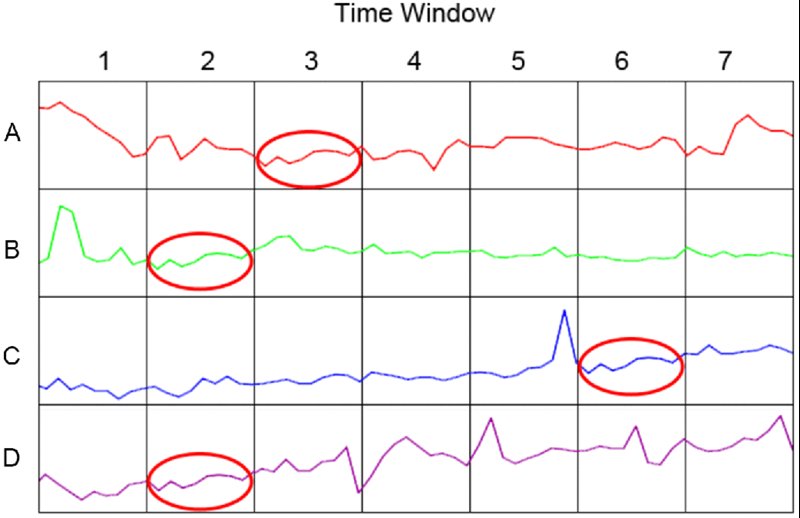

However, in the high-tech industry of semiconductor manufacturing, many factors that are interrelated affect the yield of fabricated wafers. Engineers who rely on specific domain knowledge cannot find possible root causes of defects rapidly and effectively. (See Figure 16.1.)

Figure 16.1 Time Series Similarity

In addition, when conducting similarity analysis for the time series data, the company also needs to identify and report separately the similarity according to the definable time windows; users are allowed to adjust and define these time windows when necessary. For example, in Figure 16.1, the similarity of time window 1, 5, 6 in time series A has a stronger similarity pattern than the others. Companies can decompose these time ...

Get Big Data, Data Mining, and Machine Learning: Value Creation for Business Leaders and Practitioners now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.