Chapter 2

Fundamentals of Inkjet Technology

2.1 Introduction

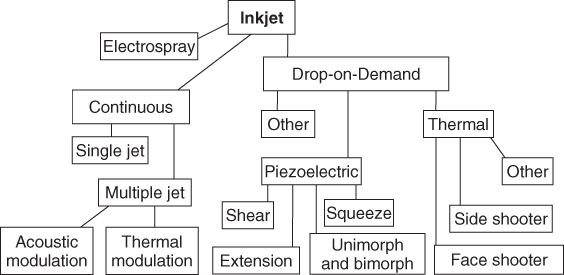

Inkjet printing involves the production of small drops of liquid and their deposition in precise locations on a substrate. Many methods for drop generation have been devised, but currently the most important methods for inkjet printing are described as either continuous inkjet (CIJ) or drop-on-demand (DOD). Inkjet technology has been further categorised in several ways (Le, 1998), but here we shall use the classification shown in Figure 2.1, which also includes the electrospray technique described in Section 2.3.

Figure 2.1 Classification of inkjet technologies.

In both the CIJ and DOD methods, the liquid flows through a small orifice (usually called a nozzle). The essential difference between the two lies in the nature of the flow through the nozzle: in CIJ, as the name implies, the flow is continuous, while in DOD it is impulsive. A CIJ system produces a continuous stream of drops, from which those to be printed onto the substrate are selected as required, whereas in DOD printing the ink is emitted through the nozzle to form a short jet, which then condenses into a drop only when that drop is required. Figure 2.2 shows examples of these types of flow. The upper image (Figure 2.2a) shows a continuous jet of ink emerging ...

Get Inkjet Technology for Digital Fabrication now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.