Plastics and Composites Processing

5.1 Injection Moulding

Process Description

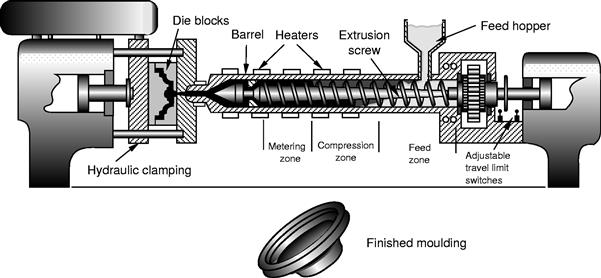

Granules of polymer material are heated and then forced under pressure using a screw into the die cavity. On cooling, a rigid part or tree of parts is produced (Figure 5.1(a)).

Figure 5.1(a) Injection Moulding.

Materials

Mostly thermoplastics, but thermosets, composites and elastomers can be processed.

Process Variations

• Injection blow moulding: allows small hollow parts with intricate neck detail to be produced.

• Co-injection: for products with rigid cores pre-placed in the die before injection or simultaneous injection of different materials into the ...

Get Manufacturing Process Selection Handbook now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.