Chapter 5

Application to a distillation process

This chapter presents a second application study, which involves recorded data from an industrial distillation process, which is a debutanizer unit. Recorded data from this process were analyzed for process monitoring purposes using PCA and PLS (Kruger and Dimitriadis 2008; Kruger et al. 2008a; Meronk 2001; Wang et al. 2003).

Section 5.1 provides a description of this process. Section 5.2 then describes the data pre-processing and the identification of an MRPLS-based monitoring model. Finally, Section 5.3 analyzes a recorded data set that describes a severe drop in the fresh feed flow to the unit and shows how to detect and diagnose this event.

5.1 Process description

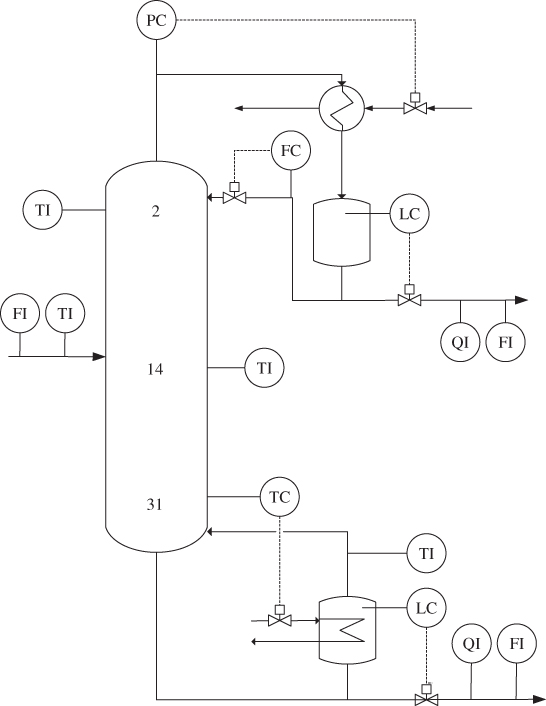

This process, schematically shown in Figure 5.1, is designed to purify Butane from a fresh feed comprising of a mixture of hydrocarbons, mainly Butane (C4), Pentane (C5) and impurities of Propane (C3). The separation is achieved by 33 trays in the distillation column. The feed to the unit is provided by an upstream depropanizer unit, which enters the column between trays 13 and 14. At trays 2 and 31 temperature sensors are installed to measure the top and bottom temperatures of the column.

Figure 5.1 Schematic diagram of debutanizer unit.

The lighter vaporized components C3 and C4 are liquefied as overhead product with large fan condensers. This overhead stream is captured ...

Get Statistical Monitoring of Complex Multivariate Processes: With Applications in Industrial Process Control now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.