6.2. Framing the Problem

In June 2008, a Six Sigma project team is assembled and charged with improving the yield of the anodizing process. Sean Cargill, a black belt for Components Inc., is assigned the task of leading the Six Sigma project.

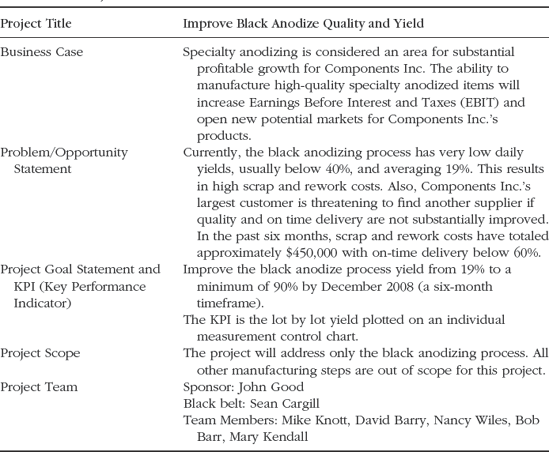

Sean brings the team together and initiates the Define phase of the project. In conjunction with the project sponsor and the assembled team, Sean develops the initial project charter, shown in Exhibit 6.2. Note that the team identifies process yield as the Key Performance Indicator (KPI). The team realizes that if this process measure improves, so will delivery performance.

Figure 6.2. Project Charter

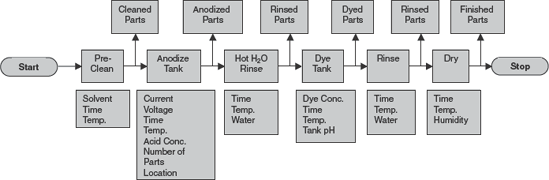

Sean and the team begin working on the project by constructing a process map for the anodizing process. To do this, they enlist the help of manufacturing personnel, which the team agrees is critical to success. Their map, shown in Exhibit 6.3, contains the basic process steps as well as key inputs (the boxes below each step) and outputs (the boxes above each arrow connecting the steps) at each step.

Figure 6.3. Process Map of the Anodizing Process

Sean then works with the team to define critical to quality (CTQ) output variables. The key measures of quality are the thickness of the anodize coating and the color of the parts. The anodize thickness ...

Get Visual Six Sigma: Making Data Analysis Lean now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.