8.11 Multistage Compressor Starting Problem

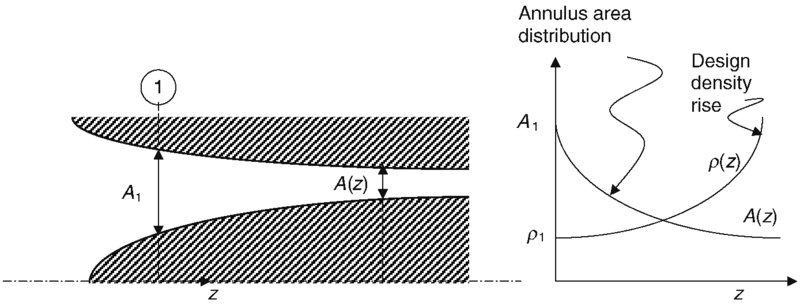

The annulus flow area in a multistage compressor is designed based on the calculated density rise along the axis of the machine operating at the design point. The assumption of constant axial velocity, for example, implies that the channel area shrinks inversely proportional to the density rise, to conserve mass, namely,

This behavior is schematically shown in Figure 8.73.

FIGURE 8.73 Flow annulus area and the density rise are inversely proportional in a multistage axial compressor

FIGURE 8.73 Flow annulus area and the density rise are inversely proportional in a multistage axial compressor

In the starting phase of a compressor, the mass flow rate is initially small, which means a higher loading for the front stages. The picture for the aft high-pressure stages is just the opposite of the front low-pressure stages. Initially, the compressor does not develop the density rise that it was designed to produce, hence with lower than design densities in the aft stages the axial velocity is increased to satisfy the continuity equation. Higher than the design axial velocity leads to a lower loading of the aft stages. Actually the aft stages would be windmilling and their blades operating in a separated flow. A comparison of the velocity triangles ...

Get Aircraft Propulsion, 2nd Edition now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.