176 Sustainable Environments

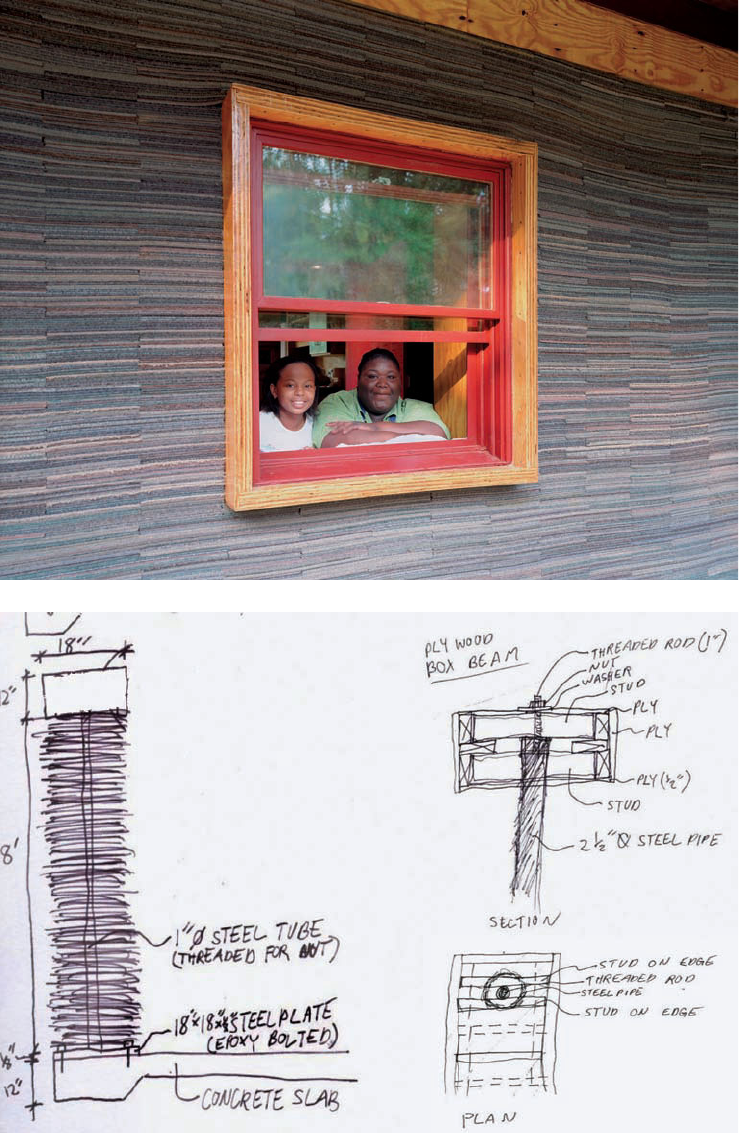

Above Right and Right Following a number

of studies and mock-ups, the wall and its

supporting structure were constructed in a

total of three weeks time, with intermittent

design and construction phases, somewhat

akin to a fast-track project. e stacked car-

pet creates a subtly patterned and multicol-

ored surface that has an welcoming tactility.

e vermilion window sashes are set into

thick, engineered wood frames, the lamina-

tions of which refl ect the stacked pattern of

the walls.

177

Above Synthetic carpeting has long been as-

sociated with indoor air-quality problems in

working environments through off -gassing.

Here, however, the salvaged tiles, reclaimed

from offi ce buildings throughout the United

States, had all been manufactured over seven

years ago. us the release of chemicals is

negligible, and the family can enjoy a safe

environment.

Salvaged and Recycled Materials

fold-up ventilation fl aps

solar power cell

blinds blinds

external light on tube

fold-up end panel, support on gas struts

ramp

adjustable legs

178 Sustainable Environments

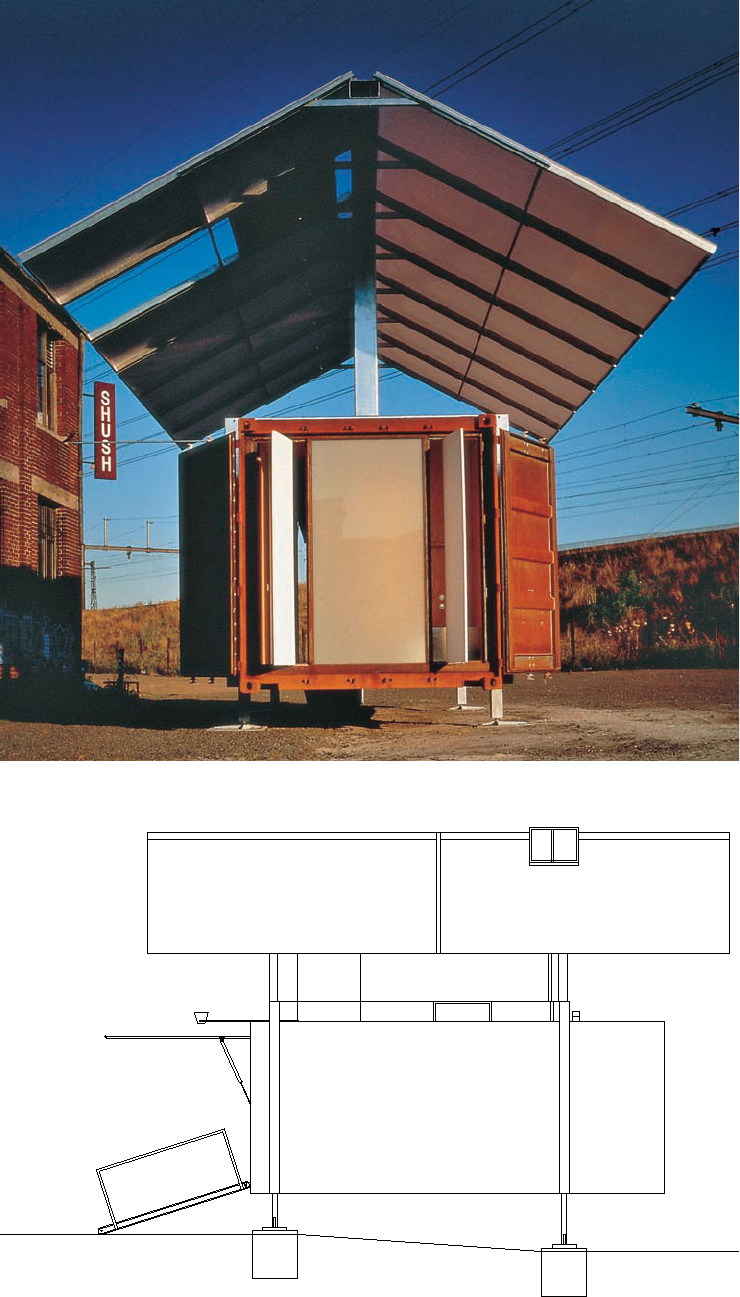

Sean Godsell Architects,

Future Shack, no fi xed site

e Future Shack is a mass-produced dwell-

ing that can be shipped throughout the world

for many humanitarian applications, such as

disaster relief, temporary shelter, and housing

for developing nations. e design takes as

its starting point recycled shipping contain-

ers. eir universality, durability, and low

cost make them ideal for the structural shell

of the house. Each unit includes a parasol

roof that shades the top of the container from

direct solar radiation and creates a protected

outdoor space for the inhabitant.

Right e shelter is self-suffi cient and may

be assembled in twenty-four hours. In addi-

tion to the parasol, the module features water

tanks, a solar power cell, a satellite receiver,

a roof access ladder, and a container access

ramp. Adjustable supports—a pair of brack-

ets with telescoping legs that are attached to

the exterior of the module—accommodate a

variety of ground conditions, with little site

preparation required.

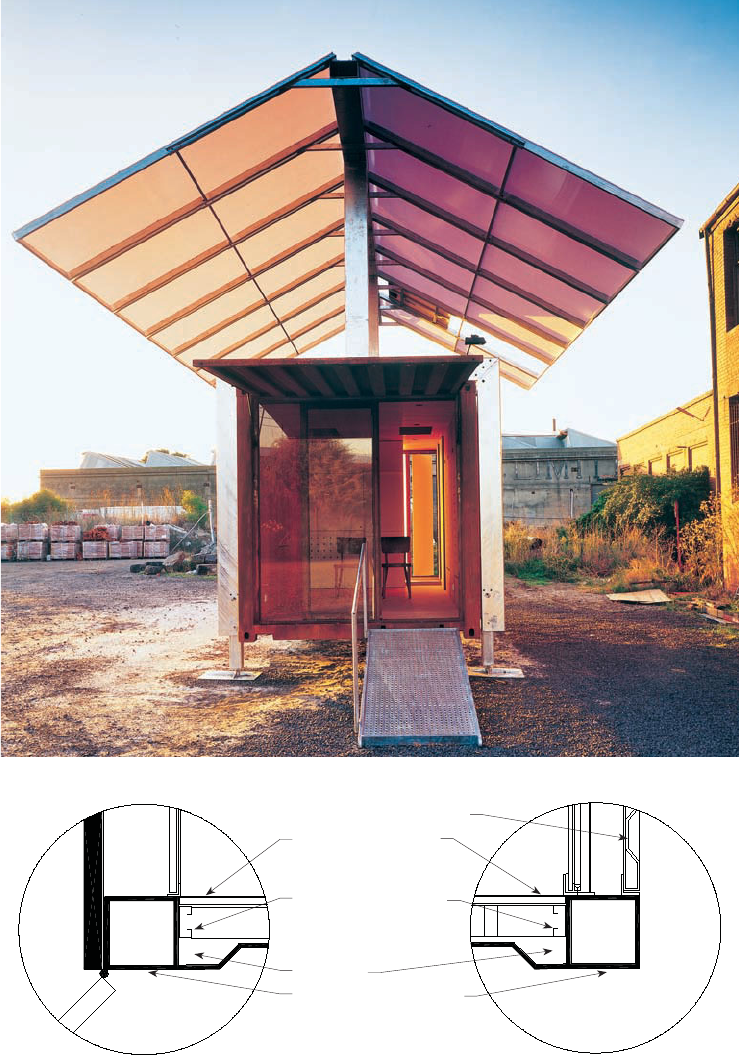

tilt-up panel to match sides of container

18 mm (3/4”) blackbutt plywood

76 mm (3”) metal studs @ 450 mm

(1’-5 3/4”) centers

R25 insulation

existing cladding, post + door shaded

179

Above Left Using recycled shipping con-

tainers takes advantage of an existing global

system of transport; it is simple to stockpile

the housing units, which are then moved by

truck, train, or ship to their new destination.

e house is thus truly recyclable, as all the

components can be stowed in the container

and transported anywhere elsewhere for

reuse.

Left e shipping container is transformed

into a habitable environment through modifi -

cations to the building envelope: R25 thermal

insulation is added to the container walls,

which are fi nished on the interior with ply-

wood; operable vents allow for the circula-

tion of fresh air within.

Salvaged and Recycled Materials

Single Speed Design, Big Dig House,

Lexington, Massachusetts, United States

e owner of the home is a civil engineer

who was involved with the Big Dig in Boston,

a major public works engineering project

that dismantled miles of an elevated express-

way for a long-awaited underground artery.

e engineer commissioned the architects to

make use of some of the enormous amounts

of construction waste generated, and over

600,000 pounds (272,155.4 kilograms) of

the free materials were incorporated into

the home as structural components. Cross

bracing on the end of the structural frame is

left exposed to articulate the separation of

load-bearing and enclosure elements. e

double-height great room is on the left, with

the living and sleeping spaces stacked within

the frame.

180 Sustainable Environments

Get Contemporary Design in Detail: Sustainable Environments now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.