Chapter 11

Inventory Costs

BEST PRACTICES

EMERGING COST-CONTROL PRACTICES

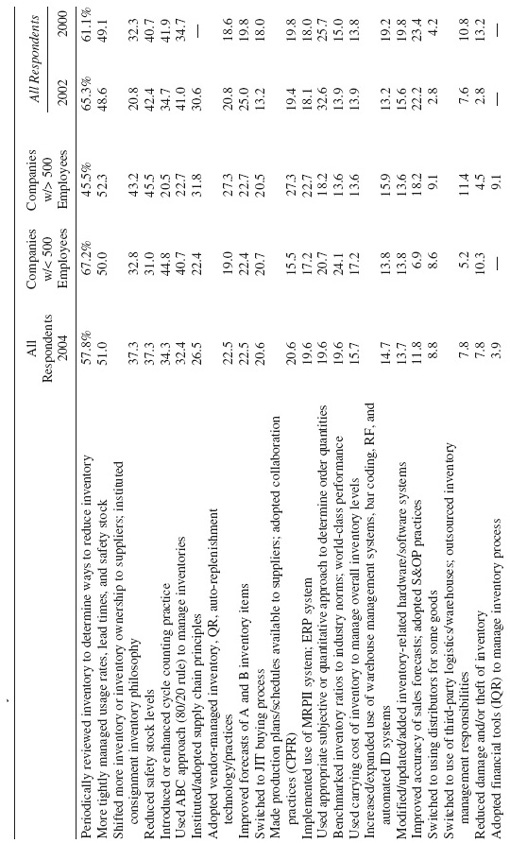

What’s happening among the top practices, according to a recent IOMA survey-called Best Practices in Inventory Management and Cost Control? In reviewing the top practices this year (see Exhibit 11.1), the following were observed:

Exhibit 11.1 Inventory Cost-Control Best Practices

- Periodic review of inventory remains the number-one best practice, but it is slipping. Even though it remains on top, as it has since the inception of the survey, its margin over the perennial number-two practice (more tightly manage usage rates, lead times, and safety stock) has declined to 6.8 percentage points, the closest spread since 1997. Typically, there has been a double-digit difference, with the widest margin (16.7 points) reported in 2002. Another sign is that for the first time since 1999, the periodic review practice garnered less than a 60% response. The periodic review process has become ingrained as a “routine” practice and is in wide use as an inventory management tool—so much so that inventory managers are moving on to other tools to gain advantage.

- More tightly manage usage rates, lead times, and safety stock: is this the next preferred top practice? If the surge among respondents from larger organizations (facilities with more than 500 employees) is any indication, this annual runner-up practice could very well ...

Get Cost Reduction and Control Best Practices: The Best Ways for a Financial Manager to Save Money, 2nd Edition now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.