Chapter 3Bulk Growth of Silicon Carbide

Bulk crystal growth is the essential technique for producing single-crystal wafers, the base material for device fabrication. Recent progress in SiC device development relies on the availability of relatively large SiC wafers with reasonable quality. At present, the standard technique for SiC bulk growth is the seeded sublimation (or modified Lely) method. However, a few alternative growth techniques have been intensively developed. This chapter describes fundamental aspects of SiC bulk growth and the associated technology development.

3.1 Sublimation Growth

3.1.1 Phase Diagram of Si-C

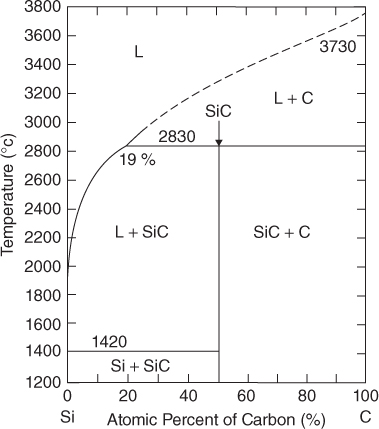

Figure 3.1 shows the phase diagram of the Si-C binary system [1, 2]. Because there exists no stoichiometric SiC liquid phase, it is impossible to employ congruent melt growth for SiC bulk growth at technically relevant system pressures. Instead, SiC sublimes at very high temperatures, above 1800–2000 °C. This is the key process of source supply in sublimation growth of SiC. The phase diagram indicates that up to 15% of carbon can be dissolved in a Si melt at about 2800 °C. Liquid phase (solution) growth, which exploits this phenomenon, is described in Section 3.6.

Figure 3.1 Phase diagram of the Si–C binary system [1, 2].

Sublimation growth of SiC consists of three steps: (i) sublimation of the SiC source, (ii) mass transport of sublimed species, and ...

Get Fundamentals of Silicon Carbide Technology: Growth, Characterization, Devices and Applications now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.