Chapter 3

Dynamics of Piezoelectric Print-Heads

3.1 Introduction

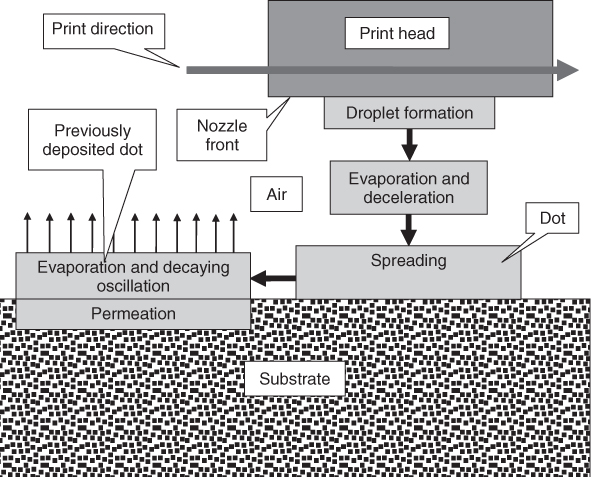

The process of depositing, on demand, droplets with a well-defined volume at a precise given location on a substrate can be split up into several unit operations as shown in Figure 3.1 (Lee, 2003; Dijksman et al., 2007; Dijksman and Pierik, 2008; Wijshoff, 2008).

Figure 3.1 Schematic diagram of the inkjet printing process. Note that permeation takes place only in an ink absorbing substrate.

Here we will consider the ink to be a solvent with a small percentage of solid material, either dissolved or dispersed. Certain inks are solid at room temperature and have to be heated above their melting temperature. Droplets are considered as free-flying volumes of fluid, which after landing form dots. After drying, solidifying and/or permeation the solid content of the ink forms a spot, this being the final result of the process.

Droplets are emitted from a nozzle and fly towards the substrate, possibly losing some mass by evaporation (Bird, Stewart and Lightfoot, 2002b) and losing some speed due to air friction (Bird, Stewart and Lightfoot, 2002a). Upon landing on the substrate, the droplet changes shape and starts spreading (Yarin, ...

Get Inkjet Technology for Digital Fabrication now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.