3

OLED Manufacturing Process

The process for manufacturing high quality OLED devices is discussed in this chapter.

3.1 MATERIAL PREPARATION

3.1.1 Basic Material Properties

As discussed in Section 2.2.2, OLED devices consist of multiple layers that have different functions. It is very important to design layers by selecting material in terms of their inherent properties and compatibility (e.g., with respect to their HOMOs and LUMOs) with other layers.

3.1.1.1 Hole Injection Material

The term hole injection refers to the injection of holes from an anode electrode, namely, ejection of electrons to the anode. The mechanism is discussed in Section 2.2.2.5. Hole injection material is used to reduce the height of the barrier (also termed a potential barrier) against hole injection from anode electrodes [1, 2]. The material layer involved in this process is called the hole injection layer (HIL).

Hole injection material is often selected so that the HOMO level is located between the HOMO of the hole transportation material and the workfunction of the anode electrode.

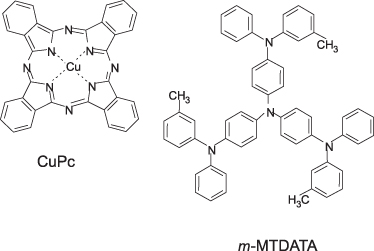

Figure 3.1 shows typical hole injection materials.

Figure 3.1 Example structures of hole injection material.

3.1.1.2 Hole Transportation Material

Hole transportation material (HTM) is used to transport holes to the emission layer [3]. This layer is called the hole transportation layer, which is usually designed with a wider ...

Get OLED Display Fundamentals and Applications now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.