ACCEPTANCE SAMPLING

Sampling involves randomly inspecting items from a lot.

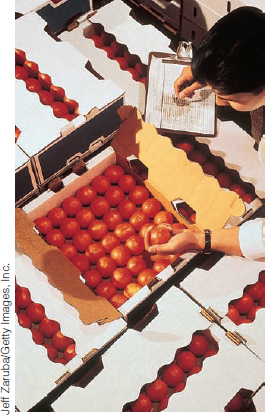

Acceptance sampling, the third branch of statistical quality control, refers to the process of randomly inspecting a certain number of items from a lot or batch in order to decide whether to accept or reject the entire batch. What makes acceptance sampling different from statistical process control is that acceptance sampling is performed either before or after the process, rather than during the process. Acceptance sampling before the process involves sampling materials received from a supplier, such as randomly inspecting crates of fruit that will be used in a restaurant, boxes of glass dishes that will be sold in a department store, or metal castings that will be used in a machine shop. Sampling after the process involves sampling finished items that are to be shipped either to a customer or to a distribution center. Examples include randomly testing a certain number of computers from a batch to make sure they meet operational requirements and randomly inspecting snow boards to make sure that they are not defective.

You may be wondering why we would inspect only some items in the lot and not the entire lot. Acceptance sampling is used when inspecting every item is not physically possible or would be overly expensive or when inspecting a large number of items would lead to errors due to worker fatigue. ...

Get Operations Management: An Integrated Approach, 5th Edition now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.