Problems

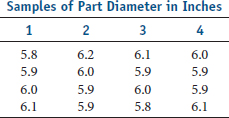

- A quality control manager at a manufacturing facility has taken four samples with four observations each of the diameter of a part.

- (a) Compute the mean of each sample.

- (b) Compute an estimate of the mean and standard deviation of the sampling distribution.

- (c) Develop control limits for 3 standard deviations of the product diameter.

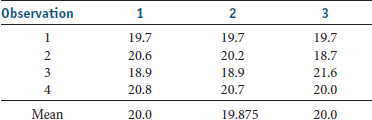

- A quality control inspector at the Beautiful Shampoo Company has taken three samples with four observations each of the volume of shampoo bottles filled. The data collected by the inspector and the computed means are shown here:

Samples of Shampoo Bottle Volume in Ounces

If the standard deviation of the shampoo bottle-filling operation is 0.2 ounces, use the information in the table to develop control limits of 3 standard deviations for the operation.

- A quality control inspector has taken four samples with five observations each at the Beautiful Shampoo Company, measuring the volume of shampoo per bottle. If the average range for the four samples is 0.4 ounces and the average mean of the observations is 19.8 ounces, develop 3-sigma control limits for the bottling operation.

- A production manager at Ultra Clean Dishwashing Company is monitoring the quality of the company's production process. There has been concern relative to the quality ...

Get Operations Management: An Integrated Approach, 5th Edition now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.