THE LEAN APPROACH TO ZERO DEFECT

THE LEAN APPROACH TO ZERO DEFECT

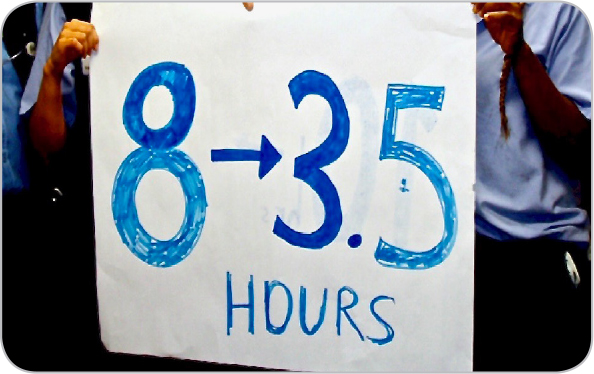

In one week, this REC Team reduced the changeover downtime on an ice-cream filler by 56%.

In the United States, Lean typically has not been applied to manufacturing processes in which one or more individuals perform a series of tasks to complete a job. The common definition of Lean is simply the practice of searching out all production activities that do not create value for the end user and so are considered waste, and then eliminating those wasteful activities.

At this point, I would like to tell a story ...

Get ReducedEffort® Changeover now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.