4

Equipment Efficiency: Quality and Poka-Yoke

Shigeo Shingo developed a system to improve inspection tasks with the goal of guarantying 100 percent quality for manufactured parts, leading toward a defects-free process. This chapter will explain inspection processes based on unnoticed mistake-proving devices (called poka-yoke). This type of inspection strategy complements statistical process control (SPC) and is used primarily for inspecting logical features.

Poka-yokes are visual and physical tools that should be used in conjunction with source inspection (a concept also created by Shingo) in order for the two techniques to be effective. Source inspection also will be presented in this chapter.

POKA-YOKES

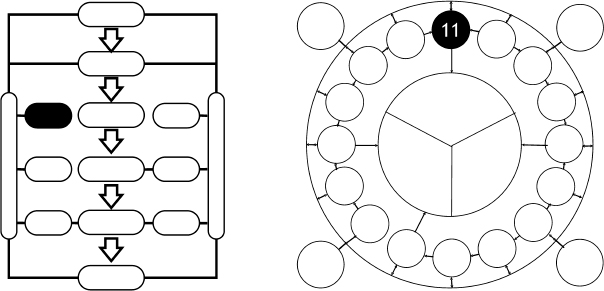

The elimination of defects using poka-yokes is part of the just-in-time (JIT) philosophy and is included as one of the 20 keys (key number 11) of lean manufacturing, as shown in Fig. 4.1. Poka-Yokes improve the quality (reduce the defect rate) that is part of the overall equipment efficiency rate (Fig. 4.2).

Figure 4.1. Location of poka-yoke in just-in-time and 20 keys diagrams.

THEORETICAL BASIS

Inspection and Statistical Quality Control (SQC)

Every production process generates defective products. The objective for all quality control systems is to reduce the number of defective parts. There are two types of defects: isolated (a crack appeared on a product) or sequence (repetitive) ...

Get Improving Production with Lean Thinking now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.