SIX SIGMA QUALITY

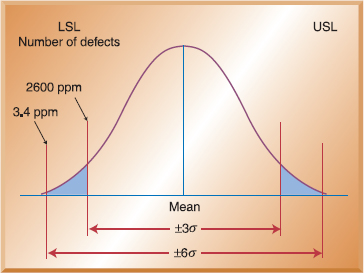

The term Six Sigma® was coined by the Motorola Corporation in the 1980s to describe the high level of quality the company was striving to achieve. Sigma (σ) stands for the number of standard deviations of the process. Recall that ±3 sigma (σ) means that 2600 ppm are defective. The level of defects associated with Six Sigma is approximately 3.4 ppm. Figure 6-10 shows a process distribution with quality levels of ±3 sigma (σ) and ±6 sigma (σ). You can see the difference in the number of defects produced.

![]() Six Sigma quality

Six Sigma quality

A high level of quality associated with approximately 3.4 defective parts per million.

FIGURE 6-10 PPM defective for ±3σ versus ±6σ quality (not to scale)

LINKS TO PRACTICE Motorola, Inc. www.motorola.com

To achieve the goal of Six Sigma, Motorola has instituted a quality focus in every aspect of its organization. Before a product is designed, marketing ensures that product characteristics are exactly what customers want. Operations ensures that exact product characteristics can be achieved through product design, the manufacturing process, and the materials used. The Six Sigma concept is an integral part of other functions as well. It is used in ...

Get Operations Management: An Integrated Approach, 5th Edition now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.