Chapter 7Who Carries Out Process Improvement at Toyota?

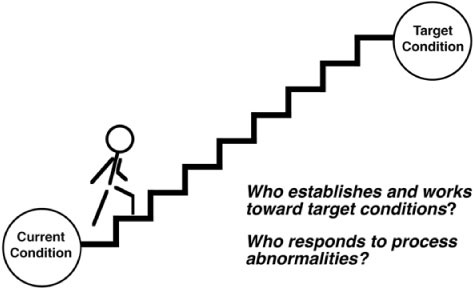

A question that has been debated for many years is: “Who should carry out process improvements?” (Figure 7-1). Here are three common but problematic answers to that question.

Figure 7-1. Working toward a target condition

1.The process operators? One of the widely held opinions about continuous improvement at Toyota is that it is primarily self-directed, with teams of production operators autonomously making improvements in their own processes. Some typical comments along these lines are:

“The operators are closest to the process and are empowered.”

“How can we get our line operators to solve ...

Get Toyota Kata: Managing People for Improvement, Adaptiveness and Superior Results now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.