Chapter 1. Car Power Basics

Hacks 1-11: Introduction

Home electronics and car electronics are quite different. Homes are designed to power dozens of large appliances; cars are designed to power a handful of small electronic devices. Homes run on high voltages that could give you a heart attack; most of the electricity in a car won’t even give you a shock.

This chapter is going to give you a rapid-fire, metaphor-rich tutorial on electronics, and automotive electronics in particular. It will go over key terms, such as voltage, amperage, and wattage, and give you a basic understanding of how to do arithmetic with these numbers. The goal is to get you up to speed quickly on car electronics, and show you the essential system upgrades that will help you hook up and power your in-car computers and accessories.

Understand Car Electrical Systems

Different electronic systems, such as those for houses, cars, and computers, use very different connectors, voltages, and power levels.

If you are familiar with only home or computer electronics, you will need a little bit of background before you start playing with the wires in your car. This hack will introduce you to automobile power. Because you will probably want to “bench test” your in-car computers in the house before installing them in your car, it will also show you how you can hack a computer power supply to power your in-car accessories indoors.

The first term you need to learn about is voltage, which is simply the amount of potential (work, force, energy, change) in an electrical flow. Different devices are designed around a certain level of electrical potential, which can be thought of as the amount of pressure propelling the electricity. The analogy most often used to explain voltage is water flow, where the pressure of the water coming out of a hose is like the voltage, which can be turned up and down by a valve or spigot. The same hose can release high-pressure water to clean a driveway, or a low-pressure flow to fill a water balloon.

Electricity, however, doesn’t flow readily through the air like water does. Electricity travels well only through conductors, such as metal wires, and in order to flow it requires a return path (usually called the ground) going back to the source of the voltage. In our water metaphor, the ground would be represented by a drainpipe. (Of course, water conveniently doesn’t require a returning drainpipe to flow.)

Another, slightly more accurate analogy for electricity is that of water pouring over a cliff. The cliff represents the positive (or +) end of a battery, and the electricity flows from the high cliff down to the ground (negative, or–). The higher the cliff, the higher the voltage. However, I’ll continue to use the hose-pressure metaphor because of the corresponding analogy between wires and hoses.

Computer Voltages

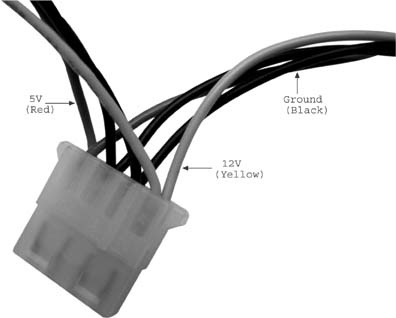

Internally, computers run on several different voltages. The power supply, like the one seen in Figure 1-1, delivers all these voltages through the various colored wires that come out of it and connect to the motherboard. The black wires generally represent the ground, which allows the electricity to go back to the source and complete its round trip, or circuit.

The voltage going into the power supply comes from a wall outlet. This provides between 110V and 240V, depending on the country you are in. The computer power supply converts this high-voltage input into the various output voltages needed by the motherboard and computer peripheral devices. (To use a standard PC power supply in a car, you need to install an inverter to increase your car’s 12V to 120V [Hack #11] ).

The computer uses many different voltages for different chips and devices. Three voltages usually supplied by the power supply are 12V, 5V, and 3.3V. Many chips run on 5V; others run on 3.3V. Modern CPUs use even lower voltages, such as 2.2V or 1.8V, but the motherboard usually converts the higher voltages from the power supply to provide these lower voltages. The primary two voltages that come out of the power supply to power devices are 12V and 5V. 12V is good for powering motors such as those in hard drives, fans, and CD-ROM drives. 5V is good for powering the electronic circuit boards that these devices use. Figure 1-2 shows the four wires that peripheral connectors on standard computer power supplies have: 5V, 12V, and two ground wires.

Car Voltages

The electricity in your car comes from its battery. Though this large battery is referred to as a 12V battery, it’s actually in the 13V range when fully charged and can dip down to 11V or lower if you leave a light on and discharge it. During engine cranking (starting the car) [Hack #45] voltage can dip down to 8V or lower, and if your PC power supply isn’t designed to handle this it will hang or reboot your computer.

Computers are not very tolerant of voltage changes like this. For this reason, computer power supplies ensure that, no matter how the input voltage bounces around, the output remains stable. This is called voltage regulation. Automobiles, however, provide much sloppier, unregulated power. Automotive “12V” is more of an average than a precise voltage. Because of this, most devices built for cars have their own power supplies that also regulate the voltage.

Traditionally, most third-party car electronic devices plug into the cigarette lighter socket (so named because its original purpose was to provide a method to light cigarettes). Even though most cars don’t come with cigarette lighters anymore, the standard power outlet shown in Figure 1-3 remains and continues to be utilized.

Tip

In cars, the entire metal body of the vehicle is usually connected in some way to the ground. Older cars run a single 12V wire to the cigarette lighter outlet center, and the outer shell of the outlet is then simply connected to the metal dashboard. Newer vehicles are made of plastic and vinyl, with some paint-coated metal thrown in, so they run both the ground and the 12V wire to the outlet.

The Key to Car Power: Off, Accessory, On/Ignition, and Crank

You probably don’t think about it when you drive a car, but the position of the key switch determines where the electricity of the vehicle goes.

There are actually two kinds of power outlets in modern vehicles: switched and unswitched. Switched outlets are on only when your car key is in the accessory or on positions. Naturally, when the car is on, any devices you have are on. When the key is in the accessory position, all of your accessories (such as the radio and any devices that are plugged in) are running. When the car is off, any switched power outlets are turned off, and usually the radio goes off too.

Unswitched outlets and hardwired accessories are always connected to the car’s battery, whether the car is off or on. Car alarms are all wired this way, which is why they are designed to draw very little power. If you’ve ever left your lights on and come back to find that you can’t start your car, you know why low power draw is important.

When you are cranking the engine to start the car, most accessories (including switched outlets) are turned off temporarily so that all the battery power can be devoted to starting the car. Fans, power windows and doors, radios, amplifiers, and most lights observe a “moment of silence” as the car starts. Because the battery must turn a heavy motor that cranks the entire engine, the voltage to all hardwired and unswitched devices usually sags during engine cranking, dropping from 12V to 9V or even lower. Thus, devices that must always remain on have to use very little power and endure wild variations in car voltage from time to time.

Discovering if Your Car Power Outlet Is Switched

Learning whether your power outlet (i.e., the cigarette lighter adapter) stays on when the car is off will help you determine whether you need to run additional power outlets for the devices you intend to use or install in your car.

To test your outlet, you need a device with a light and no battery, such as a cell phone charger with a light on it, or a small map light that plugs into a car power outlet. Plug in the device and observe it when you turn your car on and off. If the light or indicator is on only when the car is on, you have a switched outlet; if the device stays on no matter what, you have an unswitched outlet. It is generally a bad idea to leave devices plugged into an unswitched outlet.

The Hack: Making a 12V Power Supply for Indoors

If you’re going to start hacking around with cars, you’re going to want to bench test your in-car experiments and devices indoors. You may be working on your installation projects for several days, and you probably won’t want to have your dashboard (or someone else’s dashboard) torn open for that whole time. If you like to spend money, you can go buy a cool 12V power supply (such as Radio Shack part #22-504) with a nice car outlet on the front so you can do all of your testing out of the vehicle.

If you’re a computer hacker, you probably have a few computer power supplies hanging around. Since these output 12V, it’s simply a matter of making these power supplies operate with a switch to power a cigarette lighter jack.

If you have an old AT power supply (usually found in PC computers that run slower than about 200 MHz), you’re set—just pull out that old Pentium 90 power supply, front-panel rocker switch and all. Figure 1-4 shows how you can splice, twist, or cleanly solder the car power socket to the black (ground) and yellow (12V) wires of the AT power supply that would normally go to a hard drive or CD-ROM drive. Make sure that the outer shell of the outlet connects to ground and that the bottom center of the outlet connects to 12V. Ignore the power supply’s red (5V) wire; the car power socket doesn’t use it. You can purchase a car power socket for a few bucks at Radio Shack (part #22-540).

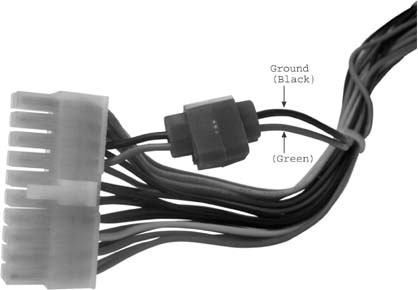

If you have a modern ATX power supply, it is designed to be controlled by software (“soft power”) that switches it off and on or puts it to sleep and wakes it up. To override this behavior, you simply need to connect the green wire on the ATX connector to any black wire, as shown in Figure 1-5. Then, the power supply automatically outputs 12V when it is plugged into the wall. (This trick works best with a power supply that has its own switch.) If the ATX power supply does not have a switch at all, you can simply connect some sort of switch between the green wire and ground, and then you can turn the 12V off and on without having to unplug the power supply.

Prevent Electrical Fires

Only you can prevent electrical fires (as the paraphrased saying goes), and fuses are an essential form of prevention.

In any electrical system, it’s important to protect against miswiring that can result in device damage or even fires. This hack explains voltage, amperage, and power levels, and points out several of the safety features (i.e., fuses) of your automobile’s electrical distribution system.

Amps

“Understand Car Electrical Systems” [Hack #1] defined voltage as the amount of potential or pressure behind electrical flow, and gave the analogy of a high- or low-pressure hose. To explain current in terms of water, we would be considering how many gallons of water went through the hose per hour. A very unscientific conceptual definition of electrical current (measured in Amperes, or amps —not to be confused with sound amplifiers!) is simply how many gallons of electrons pass through the wire per hour.

It’s pretty simple: if you’re trying to power a small device, such as a light in your car, you only have to give it a few teaspoons ( milliamps, or mA) of electrons every hour. If you’re trying to power your car radio, you need a cup of electrons every hour (amps, or A). If you’re tooling around town in your electric car, that’s where the gallons of electrons ( kiloamps, or KA) come in.

To continue our simplified analogy here, the more amps you need for your device, the bigger your “hose” or wire should be. “Gauge Your Wires” [Hack #3] discusses the different sizes of wire and how thick they should be for a given application.

Fuses

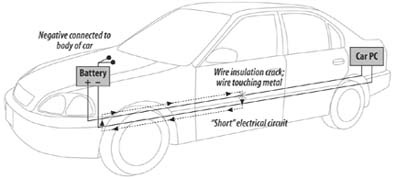

Fuses are protective devices placed along the path of an electrical circuit. To fuse means, basically, to melt. Fuses melt to protect the circuit, wires, and devices when you put too much current (electrons per second, or amps) through them. You usually get too much current going through a wire because of a short circuit, which is when wires that shouldn’t be touching touch. In a short circuit, the electricity that is supposed to go all the way to some device, such as a radio or light bulb, takes a direct path back to the battery. In other words, if the wire that is trying to bring 12V to the device gets loose and touches some metal in the car, the electricity tries to take a shortcut back to the battery through this metal (a “short” circuit, shown in Figure 1-6). Because this shorter circuit has no device to use the electricity, the energy simply heats up the wires, and if there is no circuit breaker or fuse, the wires will melt and possibly cause a fire.

To protect against this situation, a fuse of a specific amp rating is put in the line between the battery and the device it powers, close to the battery itself. If a short circuit develops in the wiring or if the device malfunctions, the fuse simply melts once the amps get too high.

Automobile fuses come in several different varieties. There are small and large blade-edge fuses, small cylindrical fuses, and plastic fuses with metal strips. There are also fusible links, which look like wires but will melt like fuses at the rated current, as well as circuit breakers, which can be reset without replacement after the short circuit is repaired. If you’re installing new fuses in the car, you can use either the very common blade-edge fuses or whichever ones your car already uses (so you can share the spares).

There is usually a location in the car where most of the fuses go, called the fuse box. It may be found under the hood, inside near the driver’s ankles, in the glove compartment, in the trunk, between the dashboard and the door, or in some other location, depending on the car. As you can see in Figure 1-7, the fuse box contains a large number of fuses, each protecting a section of the car or a particular device, such as the radio, headlights, tail-lights, A/C unit, and so on. If the dashboard lights won’t turn on even though the rest of the car seems fine, chances are the fuse has melted.

The manual that came with the car when it was purchased new, or a Haynes or Chilton’s manual from any Pep Boys, should tell you the layout of the fuses in your car’s fuse box and the proper amperage ratings of these fuses. Many cars have this diagram right next to the fuse box itself.

Fuses are rated for different amperages, and you should use a fuse just above the amperage that the device will draw. If a device is designed to draw 5A normally but can spike to 8A when it first starts (common for situations where a mechanical arm or switch activates at first, such as a CD loader or motor), it would be safe to use a 10A fuse for the device. If you used a 20A fuse and the device short-circuited internally, the 20A fuse would be very slow to “blow” or melt and would probably not save the device from further damage. The 10A fuse would start to melt as soon as the current went over the normal level, largely protecting the device and the wires that bring it power and possibly preventing a fire in your car.

Warning

When a fuse melts, it’s important to figure out why it did. If you were working on your radio while the car was on, you saw the red wire touch the metal frame, and now your radio doesn’t turn on at all, you can be fairly certain that it was your fault. But if you’ve replaced the fuse for your taillights three times and it keeps blowing, chances are there’s a short circuit you need to find and fix before you keep wasting fuses.

Protecting Your Devices with Fuses

Although the car has its own set of fuses, you may add devices that bypass the normal car power. Perhaps your power line goes straight to the battery, or your device connects, along with a lot of other devices, to a 20A fuse. You don’t want a short circuit on your device to take out the fuse for all the gadgets in your trunk—you’d like to be able to tinker with your amplifier or car computer and know that you’ll be able to conveniently replace the fuse right there if you accidentally cross wires.

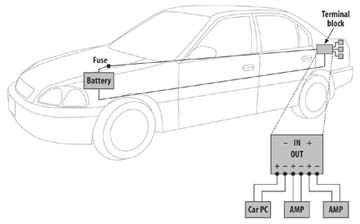

You can insert a fuse anywhere you want using an in-line fuse connector (the “in-line” refers to the fact that you put the fuse wire in a line between your battery and the device it protects, as in Figure 1-8). It’s generally better to put the fuse closer to the power source—that way, the length of the wire run is protected by the fuse.

Warning

If you’re connecting wires directly to the battery, your fuse should always be within a foot of the battery. This is because if there is a collision or the wire wears out and touches the body of the car, it could cause a fire. The closer the fuse is to the battery, the less unfused length of wire there is to cause trouble.

In-line fuses are available at hardware shops, car stereo shops, Pep Boys, and similar locations. To use them, simply choose the lowest fuse rating that will still pass enough power to your device at its peak power usage, and then connect the fuse wire between the power source (i.e., the battery or wherever you are getting your 12V) and the device.

Here are some important tips for in-car wiring:

Fuse the positive (red) +12V wire.

Never run a wire to your device from the battery without a fuse.

The positive charge uses red wire; the negative charge uses black. Invest in red/black sets of 16-,14-, and 12-gauge braided wire. Avoid solid-core wire (the stuff that’s hard to bend and keeps its shape), because it’s not designed for automotive use.

When grounding to the body, use a crimped-on washer post connector (which adds a circle to the end of the wire) and a metal screw to go into a small hole drilled in the body. If you use a metal screw with both a hexagonal nut and a Phillips-head top, you’ll be able to tighten it with whatever tool you have handy.

If you need help on wiring, see “Connect Your Wires” [Hack #4] .

Gauge Your Wires

The general rule in car wiring is that the thicker the wire is, the better. However, thick wire is expensive, and financially it’s worth learning how thick a wire you really need to bring power to all the devices you add to your car.

The width of wires is usually given in a unit called gauge. As with shotguns, a smaller number represents a bigger diameter. Continuing our electricity-as-water analogy, the wider your wire is, the wider a “pipe” the electricity has to go through. Thus, if you are trying to carry a lot of power to your trunk to power a small studio of TV screens, computers, and audio amplifiers, you will want to use a thick wire. But how thick?

Using a wire that is too thin can be a fire hazard: too much amperage will overheat the wire, potentially melting the insulation and lighting the carpet on fire. However, using a wire that is too thick can be a financial hazard: you will spend hundreds of dollars on wires alone and have no money left for gadgets.

Wire Sizes and Amp Ratings

Wire comes in several types, including solid core, which is just thick, bendable copper, and stranded, which consists of many smaller wires braided together. For automotive applications, stranded wire is more desirable than solid because it’s more flexible, especially at colder temperatures.

The maximum amps a wire can carry safely depends on the gauge and length of the wire. You probably won’t be running wire longer than about 6 meters (20 feet) in a vehicle, but it’s good to know that the longer you run the wire, the thicker it should be, because some of the electricity gets lost along the way as heat.

Wire gauge differs in the U.S. and Europe. In the U.S. you will see the term AWG, for American Wire Gauge, which I will be using here. As mentioned before, gauge is a bit odd in that the larger the wire is, the lower its number is. (Europe uses a more sensible metric-system-based wire gauge scheme. I won’t cover it here, but I will give you the metric equivalents of the AWG numbers so you can visualize how thick the wires are.)

If you are comfortable inside a computer, you are probably already familiar with several gauges of wire. The wire used to connect the reset/power buttons and front panel LEDs to the motherboard in most computers is between 24 and 22 gauge (about 0.5 mm in diameter). The wires that come out of a power supply to the ATX power connector on a motherboard are 18 gauge (about 1 mm in diameter), as are the yellow/black/red wires that go to peripherals.

To carry 12V around a vehicle, you will normally use 18-gauge and larger (i.e., smaller number) wires. The red or yellow 12V power cord in a dashboard going to the back of the radio might be 18 or 14 gauge (1–1.5 mm in diameter).

Wires get hot, and when you bundle them in groups, they get hotter. Thus, while 18-gauge wires are rated to carry 16A (according to the AWG Handbook of Electronic Tables and Formulas), this rating decreases tremendously when the wires are bundled and wrapped and run together in a plastic sheath under the carpeting.

There are many tables online (Google “wire gauge table”), most with somewhat conflicting data. Generally, you will use the gauges 12 (20 mm), 10 (25 mm), 8 (33 mm), and 4 (about 50 mm, or 0.5 cm). If you are powering a single device under 5A, 12-or 10-gauge wire can handle it. If you are going to power a full-sized computer, or several devices, use an 8-or 4-gauge wire. These are thick, heavy-duty cables that look like they should be powering a big motor. In fact, 4-gauge wires can be used to bring power to a winch, so they should certainly handle your in-car PC. 2-gauge wires (64 mm in diameter) are overkill, and if you go any thicker than 2 gauge, you’re probably using the same size wire as the battery to the engine. If you need that many amps, you might consider adding another battery in the trunk [Hack #10] .

Tip

You should use the same gauge for the ground wire as you use for the 12V wire you run to your device, as the current path is only as thick as your thinnest link. Also, run the ground and 12V wires straight to the battery, with a fuse near the battery between the 12V wire and the positive battery terminal. Try not to tap off other connections if possible, unless you’re powering a low-power device (not a computer or screen). This includes the chassis (car body)—even though it is connected to the negative battery terminal, this can add noise to your audio system or device.

The Hack: Powering Everything

A quick way to determine your power needs is to double the amperage you need to power, because when devices first turn on, they draw a lot more current. This “spike” in current needs to be accommodated. Thus, if you know your computer will run at 200 watts (200W / 12V = 16A), you should double that to 32A and add that to the amperage required by any other devices you are running (amplifiers, subwoofers, etc.) before you decide how thick a power line to run and what fuse to install.

8-gauge wire (about 33 mm in diameter) can easily carry 50A (600W) to the trunk, and 4-gauge wire (about 0.5 cm in diameter) can carry over 100A (1200W) to the trunk. A 2-gauge wire (64 mm) can carry upwards of 150A (1800W).

To tap directly into the battery, you need an additional wire tap for the battery terminals. Whether your battery has posts or screw-down connectors, it’s as simple as purchasing an inexpensive extendable connector (Figure 1-9) that enables you to stack on a few connectors. A small power distribution block mounted next to the battery is even better if you have more than a few additional power lines to run. A power distribution block is a hub that receives power from the battery and splits it neatly into several fuse-protected terminals (places to connect a wire). There are many “show-quality” devices that are translucent and have big, pretty fuses. Your budget and appearance concerns will dictate how elaborate a power block you purchase. You can use one large fuse between the power and this block, and it can be used to turn off all power in an emergency or just act as a backup fuse for your system. Make sure the distribution block has a protective cover to prevent any short circuits.

If most of your devices are going to be in the rear of your vehicle, Figure 1-10 shows an excellent way to provide ample power for all your devices: running one very thick wire to a power distribution block in the trunk.

Connect Your Wires

There are several ways to do in-car wiring: quick-and-dirty, functional, or professional, depending on who’s going to see it and how long you want it to last.

In the process of hacking computers and other devices into your car, you have to connect lots of wires. Unlike the inside of a computer, where all the wires are keyed and standardized, each car has its own set of connectors, and most of these are already in use. Except for cigarette lighter power outlets, which are really more for temporary connections, there is no standard “outlet” in the trunk of your car where you can seamlessly plug in your gadgets.

What happens instead is that new wires are run to the locations where devices are installed. They are usually run under the floor carpet, or inside the plastic baseboards or framing at the edges of the seats and carpets. When the wires poke out, professional audio shops usually surround them with plastic sheathing and zip-tie them down, as shown in Figure 1-11.

Connecting Wires

There are several ways to connect all your wires. Which method you choose depends on how permanent a solution you want, your budget and tools, and how important appearances are to you.

Twist and tape.

The cheapest way to connect your wires is to twist them together and wrap electrical tape around them so they don’t short out. This is the hallmark of an amateur, but it’s my favored method when I am doing temporary installations or fixing or installing a radio while driving (er, not that I would do that).

The minimal tools required for this approach are:

Hard fingernails (or sharp teeth) to strip wire insulation

Electrical tape to insulate and protect the wires you twist together

You need to strip the plastic coating off the wire in order to expose the metal wire strands that you will be twisting together. You should strip up to an inch of insulation, as you want lots of exposed metal to make as strong a connection as possible. Then you simply take the two wires you are connecting and twist them together, clockwise or counterclockwise. You then cover the whole thing with copious amounts of electrical tape.

While this approach is extremely functional, it scores lowest on the scale of “gimped” to “crimped” to “pimped.”

Solder and shrink.

A much better, slower, but highly professional way to make permanent bonds between wires is to solder the connections.

The tools required for this approach are:

The heat shrink is a plastic, cylindrical sleeve that you put over the soldered portion of the connection and then heat up. This causes the sleeve to shrink, cleanly covering the soldered area and making it look like one tidy contiguous wire. Make sure you cut the heat shrink long enough to cover the solder bond and reach both wire insulations, and that you slip it over one of the wires to be bonded before you connect them. Also, keep the heat shrink far down one of the wires, away from where you’re soldering—the heat of the solder could preshrink your heat shrink and make it hard to work with. Figure 1-12 shows one step from this process.

While this is no mini-course on soldering, the basic concepts here are that, being careful not to burn your hands, you place the two wires together, heat them up, and then put the solder on the wires. It will flow between all the wires (if they’re braided) and make a nice solid bond.

Then, after you’ve let the solder bond cool, you slide the heat shrink over the solder bond and heat it up quickly with the heat gun/hair dryer. One hack that people use in a pinch (with good porous heat shrink, not shiny smooth stuff) is simply to hold the heat shrink in the flame of a lighter. The heat shrink will shrivel into place if you heat it quickly and evenly—it’s a skill similar to roasting marshmallows over a fire.

Crimp and save.

There are a variety of very handy crimping approaches to wire bonding, and these are excellent in any situation where you are trying to tap into an existing ground or 12V wire that already goes somewhere and that you don’t want to cut. We’ll look at three kinds of wire crimps here.

The tools required for this approach are:

One way to crimp wires together is to use a “piggyback” crimper (Figure 1-13, left). This small plastic and metal clamp can be put on one continuous wire, and another parallel wire can be bonded to it. You simply place both wires in the clip and crush it down. The metal in the crimp will slice through the insulation on both wires and connect them.

Another excellent crimp connector is a female blade plug tap (Figure 1-13, middle). This connector crimps onto an existing continuous wire and forms a T outlet that a male blade connector can tap into. This is excellent, say, if you’ve found 12V and ground wires in the trunk of your Dad’s Lexus that you want to use to plug in some device, but you want to be as inconspicuous as possible in case he decides to take the car back to the dealer after you’ve blown several fuses.

Male and female blade plugs (Figure 1-13, right) are classic crimp connectors. When professionally installed, they are good because they can be plugged and unplugged multiple times. This is important when a device is going to be uninstalled from time to time. However, the crimping tools you get with most handyman kits for these plugs tend to make such weak crimps that the ends pull off the wire on the first or second unplugging. Still, these are useful connectors, and some of them even come with their own plastic shielding, so you don’t have to use electrical tape to insulate them.

—Damien Stolarz and Lionel Felix

Calculate Your Car’s Battery Life

To make sure you don’t kill your car battery, learn how to do quick-and-dirty estimates of power drain for in-car devices.

There are a number of ways to compare battery characteristics. One of the main measurements of power storage capacity is amp-hours, which roughly means the number of hours for which your battery can put out a certain number of amps. However, interpreting exactly what this number means is tricky.

If you’ve ever seen the movie Apollo 13, you may remember the scene where the scientists and astronauts are calculating how much power they have left, and trying to come up with an escape plan that doesn’t use too much of the spacecraft’s limited power. Automotive electronics is often like that. Everything is fine while the engine is on and you’re still generating electricity. But once your car is off and you’re running on batteries, you have to count every electron, or you’ll find yourself in the parking lot holding out jumper cables and begging for a jump start.

The reason you want to know how many watts a device is using is so you can determine how long you can run it in your car, with the engine off, without killing the battery.

The Difference Between Amps and Watts

In the house, you use watts for your power-consumption math. You know that the 40-watt light bulb is the dim one you use in the small lamp, and the 100-watt light bulb is the bright one for the porch. You may also know that you upgraded your computer power supply from the gimpy 250-watt unit it came with to one that supplies 650 watts, perhaps even with glowing purple lights and an array of variable-speed fans. These numbers make sense because the power bill comes in kilowatt-hours, and you know that if you run your 100-watt light bulb for 10 hours, you’ve used 1 kilowatt-hour.

Watts are used to measure power, and to get wattage, you simply multiply the voltage times the amperage. So what’s our non-scientific definition of a watt? A watt is simply the number of gallons of electrons that flow at a given pressure. If you have a 12V battery and you flow 1A of current, you’re applying 12 watts of power. If you have a 1.5V battery and you flow 1A of current, you’re applying 1.5 watts of power. You’ve still moved the same number of electrons, but the 12V electrons had a lot more pressure behind them and thus had a lot more power. This is also why you don’t want to plug 12V into your 1.5V device; you don’t want to use a fire hose to wash your car, either.

While individual devices such as hard drives and CD-ROM drives list their current draw in amps, general calculations are done in watts. This is because in a computer, you have 120V coming into the power supply, and all manner of 5V, 12V, 3.3V, and other voltages flowing within the computer. Batteries, however, are usually rated in amp-hours—i.e., they tell you how long this battery could put out that many amps. Thus, you have an incentive to figure out how many amps, not watts, your device is drawing.

In general, to calculate watts (power), you multiply the voltage that a device is using by the current it is drawing. The formula is power (watts) = voltage (volts) x current (amps).

If you have a laptop computer, turn it over and see if it tells you the voltage and amperage draw. My laptop says on the bottom that it runs at 24.5V and that it uses a maximum of 2.64A. This means that it runs at 64.68W, or about 70W. This makes sense to me; I know that old desktop computers used 150W and 200W power supplies and that modern units have 350W and higher power supplies.

Fortunately, in a car, everything runs at about 12V. Thus, you can move between amps and watts easily and think in whichever unit suits you. If you know a device uses 60W, then you know it will draw 5A at 12V. If you know a device is using about 2A at 12V, you know it’s drawing 24W. Divide or multiply by 12—the conversion is simple enough.

Note that these are rough calculations; we’ll ignore the fact that the voltage from the battery could be 13.8V instead of 12V, or that you might be using power converters that raise or lower the voltage and lose power in the process.

Battery Capacity

A typical battery is designed to output some level of current for a certain length of time. This is measured in amp-hours (Ah). In our ongoing water analogy, this would equate to how many “gallons per hour” or “gallons per day” of electrons the battery could put out. (There are other measures of battery capacity as well; see “Upgrade Your Car Battery” [Hack #6] ).

An average car battery has an amp-hour rating of about 50 Ah. But does this mean it can put out 50A for an hour, or that it can put out 1A for 50 hours? The interesting thing about batteries is that the faster you try to pull out the electrons, the less it can provide. If you had a battery rated at 50 Ah, you could put out far more than 50 hours if you drew only 1A. For instance, if you ran all your interior lights (together, they might add up to 1A) on a 50 Ah battery, you could easily go 50 hours (about 2 days) or more. A good battery might last as long as a week.

However, if you hooked up some item that drew 50A, it would be pulling 50A x 12V = 600W. This would be like powering 10 normal indoor light bulbs, and it would kill your battery in just a few hours or less.

To be more precise, battery vendors designate the number of hours over which their amp-hour ratings apply—usually 20 hours. By specifying “50 Ah @ 20 hours,” they are saying that you get 50 Ah if you drain the battery over 20 hours. That works out to about 2.5A per hour (50 Ah / 20 hours = 2.5A). In other words, if you draw 2.5A, you should get exactly 20 hours of life out of a fully charged 50-Ah battery. If you draw only 1A, you should get more than 20 hours, but it’s hard to say how much more—perhaps 40+ hours. If you draw 5A, you will get less than 20 hours, and probably less than 10 hours because you’re draining it above its specification.

So, if you know a battery has a specific Ah rating, just divide it by 20 to get the amperage at which you could run your devices for 20 hours. By keeping your device amperage under the value you get, you should be able to get your 20 hours or more of power.

When you get to the end of the 20 hours, the battery is not completely drained. However, it will have dropped below 11 volts, and it is for all intents and purposes “discharged,” in the sense that the voltage is too low to start your car or power your device. The battery most likely also will be damaged and will have a shorter life span, as conventional car-starting batteries are not designed for deep discharge.

The Hack: Calculating Battery Drain

If you know that your in-car computer or device has a 70W power supply, you know that the device could be using up to 6A (70W / 12V = 6A). But just as you’re not using all 350W of your desktop power supply, you’re probably not using the full 70W available to this device—your device might actually be drawing only 2A. How do you figure it out?

Method one: Power arithmetic.

You can do some rough back-of-the-envelope calculations to determine how many amps or watts your devices will draw.

Most devices, such as hard drives, list their amps on the top of the case—both their peak draw (when you first turn them on) and their normal draw when they are powered. You can do some simple calculations to find out how many watts they draw. As an example, many hard drives draw around 500 mA (0.5A) of current normally, and run on 12V. If you need to know how many watts, just multiply these figures: these hard drives draw about 6W normally.

If you can figure out the draw for each device in your system, you can add them up to get the total. A Pentium 4 might draw 60–100W; a mobile Pentium chip might draw 20–30W. (I got these results by Googling “cpu wattage.”)

If you knew you had a motherboard, a hard drive, and a mobile Pentium, you could estimate that the total wattage drawn would be in the 36W range. Divide that by the 12V power supply of the car, and you would expect a current draw of 3A. Based on our earlier calculations, which determined that a 50-Ah car battery can provide 2.5A for 20 hours, you would expect to get less than 20 hours for these devices on a 50-Ah car battery.

Method two: Amp meter.

If you have a multimeter with an amp meter feature (sometimes called ammeter; most have them), you can figure out your current draw just by hooking up the meter in between your battery and your devices (as shown in Figure 1-14). You’ll be able to see exactly what the draw is, and then figure out how long you can power that device on your battery.

In our example, the computer is drawing around 2A. Our 50-Ah car battery could probably power this device for more than a day.

Testing Drain

Although these techniques give us some idea of the current drain, we still don’t know how long the battery will last when the computer is hibernating and drawing only, say,200 mA (0.2A) of current. The best way to do this is simply to connect it up and see how long it goes.

If you’re concerned about running out of power and getting stranded, you may want to look at “Add a Second Car Battery” [Hack #10] .

—Damien Stolarz and Tor Pinney

Upgrade Your Car Battery

If you want to add a lot of electrical devices to your vehicle and still be able to start it up and drive it, you may need to upgrade your car battery.

There are two primary competing purposes for the battery in a vehicle:

To provide a very high-amperage output for several seconds to start the car, then allow the engine to generate any further needed electricity.

To provide a medium- to low-amperage output for many hours when the vehicle is off, to power devices such as car alarms or the station preset memory in car radios.

To meet these two different needs, two types of batteries are used in automotive applications: conventional lead-acid and deep-cycle.

If you are familiar with laptop or mobile phone batteries using nickel cadmium, nickel-metal hydride, or lithium ion, you know that they are designed to be completely discharged and recharged many times. Conventional automobile batteries use lead-acid and are designed to put out a large current (to start the car) for a short time, and then be recharged after only a shallow discharge. If you completely discharge your automobile battery (say, by leaving all the lights on for several weeks) you are likely to severely limit the life of the battery.

Recreational vehicles (RVs) often have two batteries—one starting battery with its good starting characteristics, and one deep-cycle battery designed to put out a lower amperage for a long time and to survive deep discharge.

In addition to the starting and deep-cycle qualifiers, a few other measurements are used to compare batteries:

- Cranking amps (CAs)

This is the maximum output amperage the battery can sustain for 30 seconds (i.e., to start the car). A good battery can put out 1 kiloamp (1000A) for about 30 seconds before the voltage starts to sag. Since cold weather makes batteries very tired, another necessary comparison is cold cranking amps (CCAs), which are how many amps the battery can sustain for 30 seconds in cold weather. This number will be lower than the CAs—for instance, in the 800A range. Bigger engines (with more cylinders) and diesel engines require higher CAs or CCAs to start in warm or cold weather (respectively). In warm climates, CCAs don’t matter much; in cold climates, this becomes an important measurement—don’t underrate your battery if you want your car to start in the winter. The two measurements aren’t quite interchangeable, but they’re roughly proportional; a high-CCA battery is generally a high-CA battery, and CCAs are always lower than CAs.

- Reserve capacity (RC) and amp-hours (Ah)

Both of these terms describe how long a battery can put out a lower number of amps. Reserve capacity describes how many minutes the battery can put out 25A before the voltage goes too low. Amp-hours are defined for much lower currents, and usually specify how many amps the battery can put out for 20 hours before the voltage drops.

Convenient Power Connectors

One benefit of a battery upgrade is that you can get one with a dual-post configuration. Some vehicles have posts on top of the battery, and the battery connectors bolt around these posts. Some batteries have sockets on the side that you screw battery connectors onto. If you purchase a battery that has both, like the one in Figure 1-15, you can use the unused set to cleanly run thick wires to the trunk of your vehicle. For more on how to hook these up, see “Gauge Your Wires” [Hack #3] .

The Hack: Installing a Deep-Cycle Battery

If you are installing many gadgets in your vehicle, you will be most impacted by the amp-hours the battery provides. Most likely, you will be tapping the battery for only 5–10A, or perhaps more amps if you run your stereo at full blast for a long time while the car is off.

As mentioned earlier, a deep-cycle battery is designed for applications where there is a long time between vehicle starts, or where the battery does a lot of work while the vehicle is off (i.e., when it’s not being charged). The latter situation is what we’re trying to address.

Although deep-cycle batteries are not as good at starting, this is where the CCA and CA ratings come in. If you overcompensate with the cranking amps, you should be able to install a deep-cycle battery and have it consistently start your car, while still being resilient to the constant device draw of all your gadgets.

In your search for a suitable deep-cycle battery, you will probably encounter hybrid deep-cycle and starting batteries, or possibly marine batteries. Marine batteries are designed to deal with months of not starting and still put out a starting current; they also are designed to deal with the vibration and rocking that occurs on a boat. These features are unlikely to be of benefit to you if you have decent suspension on your car, don’t go off roading, and drive your car frequently. However, a hybrid might be a good way to split the difference if you’re in a cold climate and are concerned that a normal deep-cycle battery won’t have enough power to start your car in freezing weather.

Optima (http://www.optimabatteries.com) makes a series of battery upgrades that are extremely popular in competition cars. Their Yellow Top series, in particular, is designed to take heat, vibration, and deep discharges with minimal capacity loss (see Figure 1-15).

When you purchase your new battery, get the largest unit that will fit in the space you have and that has greater CCAs and CAs than your existing battery (assuming your existing battery is the correct one for the vehicle and successfully starts your car). Any auto shop should be able to look up your vehicle in its database and tell you what shape and kind of battery you need.

Swapping your starting battery for a deep-cycle battery will give your car a lot more electrical staying power with the simplest installation. But if you really need to run devices for a while when your car is off and you don’t want to ever risk needing a jump start, you should consider a dual-battery setup [Hack #10] .

Add New Power Connectors Throughout Your Car

Modern devices such as laptops, cell phones, and video cameras often have 12V power adapters so they can be used, or charged, from a car’s cigarette lighter outlet. If you have more devices than outlets, you can easily add more power connectors.

Some modern vehicles come with switched and unswitched 12V outlets throughout the car. If your vehicle is not so equipped, you can easily and cleanly install 12V power outlets wherever you have a plastic panel.

Let’s say you’re going on a trip. You and your friend/spouse both have cell phones, but they’re from different manufacturers, so you have different car chargers. You’ve also brought along your laptop, so the kids/passengers can watch DVDs on the way, and your iPod adapter, so you can recharge it while you’re playing tunes. You have a cold box that stays cool when it’s plugged into the cigarette lighter adapter, and to top it all off, you’ve got your video camera plugged into a power inverter [Hack #11] (you were scatter-brained and forgot to charge it, and you’re hoping to recharge it on the way so you can use it tonight).

How can you make it possible to use all of these devices simultaneously? Well, the first approach is to get one of those triple-decker one-outlet-to-three splitters, which look strange and take up a good deal of dashboard space. But if your car only has the cigarette lighter power socket that really holds a cigarette lighter, and points awkwardly up from an open ashtray (as in older Mercedes), then what you really need to do is install more outlets.

Your friends/family surely won’t mind while you implement this hack in just a few hours. You’ll be on the road in no time, and all your devices will have the power they need, where they need it.

Planning Your Wiring

The first step is simply to draw a quick sketch of where you want the outlets. The cleanest installation will be where you can find a nice flat plastic, vinyl, or other panel with a few inches of depth behind it.

Depending on whether you want to separate the wires into different fuses or put them all together, you may be able to handle all your outlets with one long pair of wires running from front to back. Pick a continuous path for the wires to flow through the car, hopefully with a minimum of pulling up carpets or pulling down headliners.

The advice in “Gauge Your Wires” [Hack #3] applies here—you want to pick a wire thickness that can handle all your devices. If you figure that each gadget draws perhaps 2A, and you plan to add 5 outlets, then a 15A or 20A fuse should be enough to handle them (and their spiking current demands when you first plug them in or turn them on), and you should have wire that can handle all this (perhaps 12 gauge or 10 gauge).

You can purchase car adapter outlets from Radio Shack, Pep Boys, and even Wal-Mart. The auto stores are likely to be cheaper and have more accessories. You want to find outlets that are designed for tidy installation in a pre-drilled hole, and if you’re lucky you will find something in stock that you can use.

If not, your best bet is the dealer—any dealer. Most new cars have an option for these power outlets, and a little rubber cap that says “12V.” These units are designed to flush mount in a hole in the plastic. You can just go to a dealer and say “I need a 12V power outlet insert,” and mumble when they ask you what car it’s for. The part should probably cost around $10–15.

If you’re still trying to leave town on schedule, you may want to just grab an external adapter from Pep Boys and go. Later, when you have time, you can do the clean installation described in the next section.

Drilling Holes

The satisfying part of this installation is when you drill the holes. Remove each panel where you’ve decided you want an outlet, together with all its little screws and clips. Be careful not to lose them, as there’s nothing that screams “lousy install” like a panel that never quite fits again. Once you’ve taken off the panel and verified that there’s enough room behind the panel for the outlet, you can then draw a circle the size of your outlet on the panel and start drilling.

Plastic is very forgiving, so if you don’t have a lot of drill bits—especially the large (approximately 1” diameter) needed for this install—you can use any wide metal blade with the same inner diameter to bore out your hole. Of course, your best bet is an exactly sized drill bit for the outlet (or a reamer); you’ll find that the bits used to cut holes for doorknobs work well for this.

Switched or Unswitched Outlets?

Assuming you’ve remembered to purchase two reels (black and either yellow or red) of 10- or 12-gauge wire and an in-line fuse assembly at Pep Boys or the hardware store, you can now tap off the power. If you want unswitched outlets (which are always on, whether the car is on or not), you can simply run your two wires to the battery terminals, tapping off the power there. You should put a fuse right near the battery, at the beginning of the 12V wire.

If you want switched outlets that have power only when the car key is in the on or accessory positions, you’ll need to locate a wire that has 12V only when the car is on. The color of this wire varies from car to car. Also, in this case, you don’t need to use a fuse—and you may want to match the diameter of the wire you find to tap off of. (It’s pointless and possibly misleading to use a thicker gauge of wire to connect to a 10A fused accessory wire.) If, however, you plan to upgrade later, running thicker wire won’t hurt—as long as you don’t later look at the thick wire and think “Okay, looks thick enough for my power drill,” fire up the drill, and melt the accessory wires it’s attached to.

You’ll find switched 12V wires in Figure 1-16, in the dashboard, behind the radio, and behind the ignition switch itself. Your best bet in this case is to get a Chilton’s or other car manual for your vehicle so you know exactly what you’re hooking up to and sharing power with and can choose a red accessory wire that has a nice big 15A or 20A fuse on it.

Installing the Power Outlets

Once you have attached your fused wire to the car’s battery, or connected to a wisely chosen accessory wire, you can run your cables under the car’s carpet or under and along the floor edge plastic or metal framing to your first outlet.

Warning

Make sure that your battery is disconnected while running the wires, or at least that the wires are disconnected. If the wire shorts with the body of the car, it can make a nice, slow, smoldering fire, or at least ruin all the wires in your dash by melting them together.

You should connect the red or yellow wire to the middle post of the power outlet, and the black ground wire to the frame or sleeve of the outlet. Depending on the back of the outlet, you will need to either splice a few wires, or use a blade-edge connector to fit into whatever factory power connector came with your expensive dealership-provided power outlet.

You can now “daisy-chain” your power outlets. To run power to the next outlet, simply run the red/yellow and black wires from the first outlet to the next, and so on. Make sure that you wire things well and use copious amounts of electrical tape as needed, to ensure that there are no exposed wires that could short with the body of the vehicle and create electrical fires.

In the time it took to do this hack, you probably could have recharged your video camera in the house; but you’ve now solved your power needs for future trips, and your car now has an outlet for every passenger. The few hours you delayed in leaving for your trip will be more than made up by the mobile entertainment you can now enjoy on the way.

Use a Huge Capacitor to Sustain Power

A large capacitor is often used to maintain bass amplifier response, and can address other problems as well—including voltage sags when the car is started.

One of the many goals of aftermarket car audio systems is to create a reverberation that exceeds the boundary of the car, shaking other nearby cars and buildings. Car audio enthusiasts have been using 1-farad capacitors for years to make sure their cars go Boom! Boom! without brownouts or voltage sags.

Bass response is the ability of the subwoofer to reproduce the low-frequency bass sounds in music with fidelity. One of the problems with subwoofers is that they need a lot of electrical energy to move the large speaker to reproduce the low-frequency bass sound waves. When the bass beat kicks hard, the speaker should instantly slam in response—but often, the car’s battery and electrical system can’t put out enough power to ensure an instant response.

I can explain this with another water analogy. Sometimes in houses with old plumbing, you lose water pressure in the shower whenever someone flushes the toilet or turns on the washing machine. Plenty of water is coming to the house via the mains; that’s not the problem. The problem is that the plumbing can’t maintain the pressure when too many demands are made on it.

Understanding Capacitors

Capacitors are one of the solutions to the problem of sagging voltage (electrical pressure). Capacitors are devices that store up electricity, like a temporary battery (think “capacity”). One of the uses of a capacitor is to help keep voltage at a constant level.

Returning to the water pressure problem, imagine you had an extra device hooked to your plumbing, which I’ll totally randomly call a capacitor. This extra device consists of a reservoir that holds perhaps 30 gallons of water. Whenever someone makes too many demands on the water system, the capacitor steps in and supplies the extra water.

So, if you’re taking a shower, and then somebody flushes the toilet and washes their hands, the capacitor has enough water to keep the pipes full for a little while and keep the pressure up. If, however, someone turns on the washing machine and someone else starts watering the lawn, the reservoir will probably run dry after a while, and the capacitor won’t be able to maintain a comfortable shower pressure for the duration.

With apologies to both the plumbing and electrical professions, this is roughly how an electrical capacitor works. Normally, the car is putting out upwards of 13V (remember, “12V” is just what it’s called; the battery actually runs higher). When the bass amplifier demands massive current, the voltage of a normal electrical system might “sag” to 12 or 11 volts. If the car was driving at night, you might actually see the headlights dimming to the beat.

With a large capacitor installed, however, the vehicle maintains the 13V that the battery is putting out. Since the beats are of short duration, the capacitor keeps the voltage up; the battery or engine puts out the current, and the audio system effectively delivers a “block-rocking beat.”

Car PC Capacitor Use

Sustaining audio output is not the only benefit of using a capacitor. Of interest to in-car computing is the capacitor’s ability to maintain voltage when, for instance, you’re starting the car. When a car is started, for a few seconds the vehicle pulls almost all the battery power for cranking the engine. During this time, devices that are connected to the car battery have to endure a voltage that drops to much lower than 12V—possibly even 7V or lower, depending on the state of the battery. If the car starts right up the voltage can come back up, but it’s often too late for the car computer that began to boot when you first turned the key and then died when you started cranking.

With a large capacitor and a good battery, it’s possible that your computer can survive car-starting without a reboot. But that isn’t the primary purpose of a fat capacitor, and buying an appropriate power supply that lets your computer survive engine cranking [Hack #45] is cheaper. Probably.

Capacitors come in several shapes and sizes. The most recognizable are the little black cans you see on a motherboard. Whenever you see a small cluster of capacitors like the one in Figure 1-17 rising up from a computer motherboard, they are often near a power source, keeping the voltage constant. You see them a lot in power supplies as well.

Capacitors are rated in farads, and the small capacitors inside electronics are in the microfarad range. You can think of farads as mega-gallons of electrons.

Audio capacitors like the one in Figure 1-18, in comparison, are huge. They can be a foot long and as thick around as a small fire extinguisher. They come in 1-farad (1F) or higher capacities. Even though this sounds like a small number, it’s not. Farads are just big units.

The capacitor enhances the battery and is installed in parallel with the battery. Usually, the capacitor is installed near the audio equipment it is supporting (i.e., in the trunk) and near the power distribution block or amplifiers.

The 12V line from the battery (red/switched or yellow/unswitched) goes to the + side of the capacitor, and the ground (usually black) wire from the battery ground goes to the–side of the capacitor.

1F capacitors for audio use come with their own mounting brackets and many of them are designed to look cool. They’re easy to install and are essential for maintaining voltage levels in demanding car electrical systems.

Upgrade Your Car’s Alternator

It’s possible to install so many electronic devices in your car that the battery continues to discharge even when the engine is running. Upgrading to a high-output alternator ensures that there’s enough power to feed all the devices while keeping the battery charged.

An alternator is a device in modern automobiles that acts as the voltage generator for the engine (Figure 1-19). While the battery does the job of getting the engine started, once the car is running off fuel it technically doesn’t need a battery anymore. You could even disconnect the battery while a car was running, and it would probably continue to run (this applies to older cars without a lot of electronics; newer cars would throw a fit because the battery keeps the voltage levels stable). If you’ve ever gotten a jump start and then driven around with a “dead” battery, you understand this feature.

Once the engine is started, it’s actually the alternator’s job to supply the electrical power for the whole car. As an electrical generator the alternator is very efficient, but its voltage tends to fluctuate. The car’s battery acts to smooth out the voltage and keep it at around 13–14V. In the process, the car’s battery gets recharged.

A normal alternator might be designed to put out 100A. This might seem like a lot, but once you start adding high-power devices with hungry CPUs, you could easily exceed this level. Once that happens, the car will act as if the alternator has stopped working—the battery will have to make up the difference between what the alternator is putting out and what the car’s entertainment system is demanding. The battery can thus become completely discharged, and for conventional batteries, this essentially makes them “dead.” If you don’t realize that the real problem is that you’ve exceeded your alternator’s capacity, you might think that your battery is dead and upgrade it to a new top-of-the line battery, only to kill that one, too.

The solution to this problem is to upgrade the alternator. You will probably want an auto shop to do the installation unless you are handy with a wrench and know how to set the right tension on a belt. Luckily, installing an alternator is almost always a simple (i.e., inexpensive) job. The alternator is usually right on top of the engine and easily accessible.

If you ever get “dying battery” or “dying alternator” symptoms such as dim headlights or difficulty starting, even though you know the battery and alternator are good, upgrading the alternator may be the solution. Also, if you’ve calculated your power requirements and they clearly exceed the 100A your alternator probably puts out (perhaps because you’ve installed your Alienware gaming machine in the trunk), you should definitely upgrade the alternator.

If you plan to upgrade your alternator, be sure you read “Add a Second Car Battery” [Hack #10] before you buy, because if you are planning on adding a second battery you may want to get a dual-output alternator that charges both batteries independently.

Add a Second Car Battery

Adding a second car battery is a great way to get lots of standby power when the vehicle is off. You can upgrade your car so that it has the same power setup as a recreational vehicle, with one battery for starting and running the engine and another for powering devices.

Adding a second battery doesn’t really increase the number of devices you can power while the car is on—for that you need to upgrade your alternator [Hack #9] . What a second battery does do is more than double your power storage capacity, increasing the time for which your devices can run when the engine is off and ensuring that your primary battery always has the power to start your car.

To illustrate the information in this hack, I’m going to appeal to your intuitive understanding of batteries. If you look at the label on AAA, AA, C, and D batteries, you’ll discover that they all supply 1.5 volts. But you would expect that a D is better than a AAA somehow, if only because it’s bigger. What you may not know is that the main difference between the two types of batteries is the length of time each battery can put out 1.5V, and how many amps they can sustain. That’s why devices that need to put out power for a long time, such as flashlights or boomboxes, use D batteries, while remote controls and pagers only need AA or AAA batteries.

You may or may not also know that you can wire a pair of batteries in parallel. The combination will output the same voltage, but for longer. For example, if you take 4 AA batteries and wire them in parallel (tops to tops and bottoms to bottoms, with wires daisy chained between them), they’ll probably be able to put out more sustained power than a single D battery, but only at the same 1.5V that a single battery delivers.

What you wouldn’t want to do is put a D battery in parallel with a AAA battery. After the AAA battery was discharged, the D battery would still be putting out voltage, and the AAA battery would be sucking it up—not the desired effect. The general rule is that you put batteries in parallel only when they are the same kind and age. Even then, if one of the batteries goes bad it can take the other ones down with it, so don’t leave a dead battery mixed in with good ones.

If car batteries are connected in parallel, the more-charged one will always be trying to jump-start the less-charged one. So, although you could simply wire a second car battery in parallel with the first, there are better and safer ways to implement a two-battery system.

Battery Isolators

One excellent way to implement a two-battery system is with a battery isolator. These devices range from less than $50 to several hundred dollars, depending on the sophistication and features. Ideally, the job of a battery isolator is to combine the power of the two batteries for everything from powering devices to starting the car, while making sure that a fault in one battery can’t kill the system. In essence, it becomes a redundant array of batteries—all the benefits of a backup battery, with none of the drawbacks. And depending on whether starting power or device power is more important to you, an isolator can make sure that devices deplete only the secondary battery, always leaving the primary battery charged to start the car.

In practice, the isolator uses a bit of the power itself ( diode isolators will drop alternator output by about 1 volt, have large heat sinks, and are somewhat inefficient). It’s not that easy to keep two different batteries fully charged, united in power, but divided in risk. Isolators come in several kinds, from simple switches that flip from one battery to another, to complex microelectronic circuits that actively monitor the charge levels on both batteries, charge them appropriately using alternator power, and use both of them to power devices and start the vehicle.

Because of the large currents needed to charge a battery, any second battery setup will need to run thick (4-gauge or so) wires from the alternator/front battery back to the second battery, unless the second battery is also being mounted near the engine. Exactly how to do this will be in the installation instructions that come with the battery isolator.

Dual-Output Alternators

If you want a very simple isolated system, you may be able to achieve it with a dual-output alternator. These are designed to charge two separate batteries independently. You can install your second battery to be charged by the secondary output of the alternator, and wire most of your devices to this second battery. When the engine is running, the vehicle will power the devices. When the engine is off, the second battery will power the devices, leaving the primary starting battery untouched and always charged and ready to start the car.

Conventional Versus Deep-Cycle Batteries

In “Upgrade Your Car Battery” [Hack #6] I discussed the two basic types of car batteries. In RVs, the usual approach is to have both kinds of batteries, each doing what they do best. A conventional, high-cranking-amps, lead-acid battery is connected to the ignition, lights, and basic car electronics. A second, big, deep-cycle battery (or several) is charged by the engine as well, but when the engine is off these batteries power devices such as refrigerators, TVs, computers, and so on.

There’s never any risk of killing the starter battery by powering nonessential accessories, and if the deep-cycle battery goes dead, no harm is done—the engine can just charge it back up on the next drive, if it’s long enough. However, keep in mind that the stock alternator isn’t designed to charge batteries from a deep discharge on a regular basis, so you may want to upgrade it as well [Hack #9] .

This arrangement depends on a good battery isolation circuit, and the same system can be installed in any vehicle with room to put an extra battery.

Battery Fumes

An important consideration when installing and using a secondary battery is the potential for battery fumes (a.k.a. poison gas). These fumes are created when a battery is being recharged. While many batteries today are “sealed” lead-acid, it’s difficult to completely seal a battery. RVs and work trucks have both their batteries vented to the outside, either in the engine compartment or on the sides of the vehicle. If you are installing a second battery in a hatchback, or even in a trunk that can allow gases into the passenger compartment, ensure that the battery you are installing is designed for this, or provide appropriate ventilation for it by building an enclosed battery box that vents to the outside of the vehicle.

Warning

Battery fumes are explosive and toxic, so a DIYer building a battery box should make sure that it vents to the outside. These gases are generated only when the battery is being charged. Consequently, deep-cycle batteries recovering from a deep discharge will produce more fumes then a starting battery recovering from an engine start.

Many battery makers recognize this dual-battery application and will tell you whether their batteries are safe near passenger compartments. As a practical note of experience, I’ve owned an Audi, a VW Bug, and a Mercedes, all of which had batteries under the back seat from the factory, so don’t be paranoid—just vent appropriately.

Put Home Power Outlets in Your Car

If you need to power a device that doesn’t come with a car adapter, or if you want to run a top-of-the-line PC that consumes 300 watts, you will need to use a device called an inverter to convert your vehicle’s 12V to the 120V or 220V found indoors.

“Understand Car Electrical Systems” [Hack #1] showed how you can convert the high-voltage power from a wall outlet into the 12V and other voltages needed by computers. If you need to power an in-home device in the car, however, the reverse can be done, using a device called an inverter.

What Inverters Do

American household voltages have been standardized at around 120V, and power in Europe generally runs at 220V. While vehicles and batteries use something called direct current, indoor voltages are alternating current. Direct current (DC) is simple: 12V on one wire, 0V on the other, and the current goes around in a loop from the 12V wire through the device and back to the 0V ground wire. Alternating current (AC) has a wavy pattern: the main two wires in AC trade off being at ±60V (in North America), back and forth, 60 times per second. (In Europe, the voltage waves ±110V, 50 times per second). The third “ground” wire in AC voltage usually connects to a metal pole sticking into the ground, and it actually acts as a failsafe return path for current if there should be a power surge, short circuit, or lightning strike. So, inverters have to do two things: they have to increase the 12V 10 to 20 times, and then they have to convert the simple DC voltage to the more complex back-and-forth AC current.

Inverters use a certain amount of the power coming into them just to convert the voltage—about 20% of the wattage is lost in translation. Thus, if your computer needs 100W to run, the inverter will draw 125W from the battery/alternator in order to supply it. In practice, you should probably have an inverter rated for twice what your devices demand. In my experience, when you first turn on devices (such as computers or power supplies for laptops) they create a big power surge, which can flip the circuit breaker built into your inverter. Then, even though the device settles down to its rated power draw, well within the inverter’s rating, the inverter will have freaked out and shut down everything. The only caveat is that too powerful an inverter will waste power (on fans and heat) and give you less running time when the car is off—but you shouldn’t be using an inverter if you’re trying to maximize battery time.

Choosing an Inverter

Inverters come in various sizes and generally look like heat sinks, as you can see in Figure 1-20. They are usually packaged in colored aluminum and have a 12V plug on one side and several outlets on the other side. They often include an easy-to-replace fuse on the outside.

The key to comparing inverters is their wattage, because each inverter is designed to power devices only up to a given wattage. (I discussed how to convert amps to watts in “Calculate Your Car’s Battery Life” [Hack #5] .)

A small inverter might be able to handle 50W, or just over 4A (50W / 12V). That means it could power a few cell phone chargers, or perhaps a laptop power converter. Larger inverters might be rated for 200W, 300W, 500W, or even 1200W. The higher the wattage rating is, the more likely it is that the unit can supply power for hungry devices such as dual-processor computers, 21” flat-screen monitors, or power tools.

If you are using a smaller inverter, you are likely to quickly exceed its power, so you have to make sure you overcompensate. Also bear in mind that almost all devices have a current spike when they are first turned on or plugged in, so if you are using a small inverter at its wattage limit, you may need to power on your devices one at a time so as not to trip the circuit breaker or fuse built into the inverter.

Powering High-Amperage Inverters

Beware of having eyes bigger than your sockets—when you see a power outlet in your car, it’s very tempting to start hooking up power strips and extension cords and treating it just like wall power, but most wall outlets can easily supply thousands of watts, whereas only the biggest inverters come close to that.

If your vehicle is off and you don’t have a dual-battery system [Hack #10] , you’re probably not going to be able to start your car for long if you use a huge inverter. Sustaining 1200W requires 1200W / 12V = 100A. As discussed in the previous hack, conventional batteries might be able to put out 25A for 2 hours, but a 100A draw is like cranking your car to start it—something batteries are designed to do for only about 30 seconds. If you’re running a huge inverter without a huge secondary battery, you’re going to need to leave the engine idling while you run your devices.

This car-as-generator approach is the same one taken by bigger work trucks and pickups. When they need to power high-voltage AC power tools, they have an inverter professionally installed in the truck and have power outlets right on the back of the vehicle. In RVs there are power outlets as well, and these run off either the power of the engine, a bank of batteries charged by the engine, or a separate, more efficient generator that runs off the gas (or even another fuel, such as propane or diesel).

The Hack: Wall Outlets in Your Car

If you really want to do a high-quality installation of power outlets, make sure that all your power supply issues are taken care of: that you have a strong enough battery to power these outlets for a while (or a secondary battery that can be completely discharged), or that you power the outlets only when the car is on.

If you have a very strong inverter but only a single battery, you probably want to make sure the inverter only powers on with the engine. First, to make sure that you won’t drain your battery while driving, read “Upgrade Your Car’s Alternator” [Hack #9] . Then, because you need to run a thick cable to supply 100W or more to the inverter, read “Gauge Your Wires” [Hack #3] .

If you need a very high-current switched output (so that the inverter is on only when the car is on), you are going to need to use another device to turn the current on or off. The reason is that the switched wires that run from the accessory or on positions of the ignition are not going to be thick 4-gauge or 2-gauge wires. Thus, you are going to need to use a device called a starter relay (see Figure 1-21) to activate the 100A current on the power wires when the thin accessory wire goes on.

The automotive relay is a simple switch. It has four terminals (wire posts): IN, OUT, 12V, and ground. You can even see from the size of the terminals which posts activate the switch and which posts carry the heavy relay current.

You can mount the relay in the trunk or the front of the vehicle; it’s probably easier to mount it in the trunk if that’s where you’re mounting the inverter. Because other devices (such as amplifiers) will want access to the unswitched high-amperage 12V, you should supply them first and then route the power into this relay, and then to your inverter.

At this point, your inverter will turn on when the car key is in the accessory position or when the vehicle is on. If you want to make sure that it is on only when the engine is actually on, you will need to consult your vehicle’s manual or an installer, who can find a switched 12V connection that’s on only when the car is on.

Using a power strip is possible with a high-output inverter, and thickly insulated extension cords are pretty safe as long as you don’t run them underneath the carpets or hide them in such a way that they might short out on the metal of the vehicle.

If you want the electrical outlets cleanly exposed for easy access or prominent display, your best solution is to install the inverter right behind the panel where you want the outlets. With this setup, you aren’t snaking these higher-voltage 120V wires dangerously around your vehicle.

Hacking High Voltages Safely

You may not have known this, but 12V of DC power is not likely to shock you. You can test this by touching the poles of your battery, one with each hand. You most likely won’t get a shock; if your hands are wet you might feel a tingle.

Wall outlet high-voltage AC is another thing altogether. Do the same trick with AC, and your body will jerk back and you’ll hurt for a while. You might get a small heart attack, or you might get “frozen” onto the wires and not be able to let go.

Warning

It’s not a good idea to run AC power through the walls of your car. If you short out the power against the body of the car, you could damage the vehicle, shock yourself, and possibly create an electrical fire.

The goal of this hack is to install actual power outlets in the walls of your car, just like those in your house. However, realize that you’re now dealing with high AC wall voltage. You do not want to run high-voltage AC wiring any distance in a car. Besides being very unsafe, it may not be legal unless installed by a licensed electrician (who may laugh at you when asked to install it). The best solution is to safely mount the inverter so that its power outlets are flush mounted with the walls of the vehicle.