19The Building Blocks of Automated Systems

In this chapter, we will consider some of the components commonly found in automated manufacturing systems. These examples show how actuation of these systems can be obtained, how control of movements can be effected and how information on the system can be fed back to the controllers.

19.1 Cams

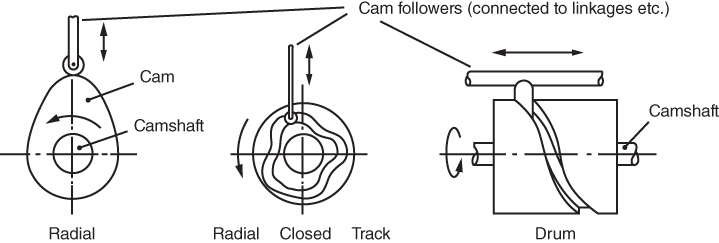

A purely mechanical component cams are probably one of the earliest control devices; these are used to control the movements of cam followers, which are in turn connected to linkages. These linkages are used to move cutting tools, pick and place devices, inspection probes and so on. Three types of cam are shown in Figure 19.1. The cam profile is machined around the perimeter or into the surface of the cam, which is usually made of steel, and it is the profile of the rotating cam that determines the movement of the follower. Cams may still be found in hard automation such as screwcutting machines where the product is produced in high volumes and is unlikely to change over a period of years. However, where product volume is not so high and product changes are more frequent, then it is easier and cheaper to control movements by microprocessor‐based programmable systems.

Figure 19.1 Three types of cam used in dedicated ‘hard’ automation.

19.2 Geneva Mechanism

Another mechanical device this is used to produce a rotary indexing movement in, for ...

Get Essential Manufacturing now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.