10

Sandwich Structure

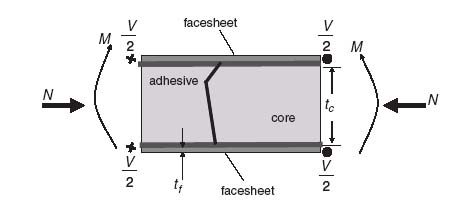

A sandwich structure (Figure 10.1) typically consists of two facesheets separated by lightweight core. Usually, the facesheets are bonded to the core with the use of adhesive but, under certain circumstances (for example, using X-cor® or K-cor® [1, 2]), it is possible to eliminate the use of adhesive.

Figure 10.1 Sandwich configuration

Composite laminates make up the facesheets. There is a variety of materials and configurations used for the core depending on the application and the desired properties: foam, honeycomb, low-density foaming aluminium, etc. Most core materials, in particular honeycombs, are anisotropic. They have different stiffnesses and strengths in different directions. In general, the purpose of the core is to increase the bending stiffness of the sandwich by moving material away from the neutral axis of the cross-section. The stiffness (and strength) of the core are, typically, much lower than those of the facesheets. As a result, for general loading situations such as that shown in Figure 10.1, with applied bending moment M and in-plane axial and shear loads N and V, respectively, all the load is taken by the facesheets. The bending moment (per unit width) is resolved into a force couple where one facesheet is loaded by a positive force per unit width Nm and the other by an equal and opposite force per unit width −Nm. The magnitude of ...

Get Design and Analysis of Composite Structures: With Applications to Aerospace Structures, 2nd Edition now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.