1.3 DEFINITION OF OBSOLESCENCE MANAGEMENT

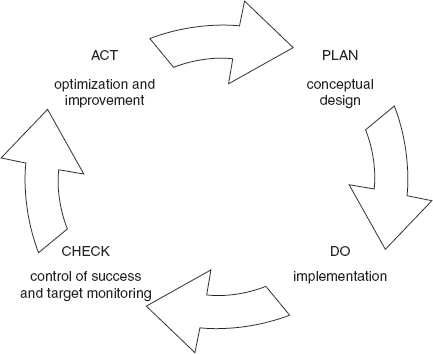

To ensure a constant qualitative performance, an obsolescence management plan should be improved continually. For example, the Plan-Do-Check-Act (PDCA) cycle shown in Figure 1-2 is an appropriate way to satisfy this goal. Developed by Dr. W. Edwards Deming, the PDCA cycle is also called the Deming Cycle or Deming Wheel (Seghezzi, 1996).

FIGURE 1-2 PDCA cycle.

To support continuous improvement, obsolescence management organizations must be provided with adequate resources to support necessary activities that are consistent with the organization’s business. The company management (for example, the chief executive officer) is responsible for providing these resources and for establishing an obsolescence management plan within the framework of a dependability management system (IEC-62402, 2004).

The management of obsolescence problems is often referred to as “diminishing manufacturing sources and material shortages” (DMSMS) (Saunders, 2006). As addressed in this book, DMSMS specifically refers to the loss of the ability to procure required materials, parts, or technology.

The process for managing obsolescence is illustrated in Figure 1-3 to mitigate or avoid the impact of supply shortfalls for all types of materials, parts, devices, software, services, and processes during the intended life of a product.

FIGURE 1-3 Process steps for managing ...

Get Strategies to the Prediction, Mitigation and Management of Product Obsolescence now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.