Chapter 4

1981: Kansas City Hyatt

Regency Skywalk Collapse

53

THE REPORTED STORY

The New York Times Abstract:

The death toll rose to 111 in the Hyatt Regency Hotel accident today, as

officials began trying to determine what caused the collapse of two walkways

suspended above the hotel lobby. (Stuart, 1981)

THE BACK STORY

KANSAS CITY HYATT REGENCY HOTEL DESIGN

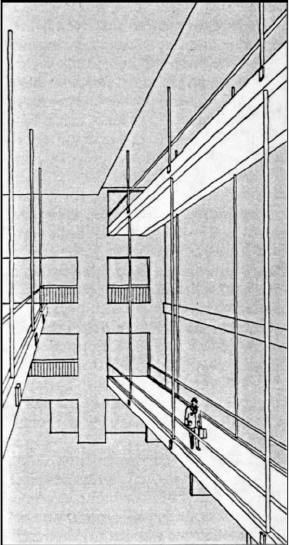

The Kansas City Hyatt Regency Hotel was designed as a hotel with three

main sections: a 40-story tower section, a function block, and a connecting

atrium area. The atrium was a large open area approximately 36 m by 44 m

and 15 m high. Three suspended walkways spanned the atrium at the second,

third, and fourth floors (Figure 4.1). These walkways connected the tower

section to the function block. As shown in Figure 4.1, the third-floor walk-

way was independently suspended from the atrium roof trusses. In contrast,

the second-floor walkway was suspended through six connections from

the fourth-floor walkway, which was suspended from the roof framing

(Pfrang, 1982).

53

Ch04-P088531.qxd 2/22/06 11:45 AM Page 53

54 Engineering Ethics: An Industrial Perspective

HYATT PROJECT HIERARCHY

Hotel development began in 1976. Design and construction were con-

ducted by specialized teams, under the direction of PBNDML Architects.

The design team consisted of the architect, mechanical engineer, electri-

cal engineer, and structural engineer. After the owner, Crown Center

Redevelopment, chose the architect, the architect then chose the rest of

the design team. The design team received a fixed fee for services ren-

dered. The construction team consisted of the general contractor, Eldridge

Construction Co., and its subcontractors, which included the structural

steel fabricator and erector, Havens Steel Co. Havens subcontracted

detailing work to WRW Engineering. The general contractor was chosen

by the owner by its bid for the contract; the subcontractors were chosen by

the general contractor by their bids.

Figure 4.1 Schematics of the second-, third-, and fourth-floor walkways, looking south.

From Pfrang, 1982. Republished with permission of ASCE.

Ch04-P088531.qxd 2/22/06 11:45 AM Page 54

1981: Kansas City Hyatt Regency Skywalk Collapse 55

The structural engineer, GCE International, was represented on this

project by Daniel Duncan, a project engineer in charge of the actual

structural engineering work. Duncan worked under the direct supervision

of GCE President Jack Gillum. Though not bound by direct contracts, the

structural engineer had certain control and authority over the construc-

tion team members through contract documents. No portion of the Hyatt

project could commence until the shop drawings for that work had been

approved by the structural engineer.

In developing structural steel aspects of a building like the Hyatt

project, the structural engineer may design and analyze steel-to-steel

members and connections. Calculations are performed to determine the

strength and adequacy of the connection to carry the loads for which it is

designed. In the corresponding structural drawings, these design details

are called out as special “section details” within the structural drawings. If

a section detail is not included in the structural drawing for a particular

connection, the fabricator receiving the drawings employs its steel

detailer to choose an applicable connection from the American Institute

for Steel Construction (AISC) Manual of Steel Construction. The steel

detailer translates structural drawings into shop and erection drawings for

use in construction by the fabricator’s construction crew. Completed

structural drawings are sealed with the personal seal of the licensed pro-

fessional engineer who prepared the drawings or under whose direction

and supervision such drawings were prepared. The seal is the equivalent

of the engineer’s signature and indicates his acceptance of responsibility

for the design shown.

After shop and erection drawings are prepared by the steel detailer, a

steel checker reviews them. The checker only checks the exact work of the

detailer. The structural engineer then reviews the shop and erection draw-

ings by the fabricator and stamps them with the engineering firm’s review

stamp. The stamp represents drawing “conformance with the design concept

and compliance with the information given in the contract documents”

(Administrative Hearing Commission, 1985).

ORIGINAL BOX BEAM HANGER ROD DESIGN

AND

MODIFICATIONS

In 1978, Jack Duncan designed the box beams and hanger rods that

were the structural steel members supporting the second-, third-, and

fourth-floor walkways. On the second- and fourth-floor walkways, 1

1

⁄

4

-inch

diameter round steel rods were intended to run from the ceiling down to

Ch04-P088531.qxd 2/22/06 11:45 AM Page 55

Get Engineering Ethics now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.