Solved Problems

(See student companion site for Excel template.)

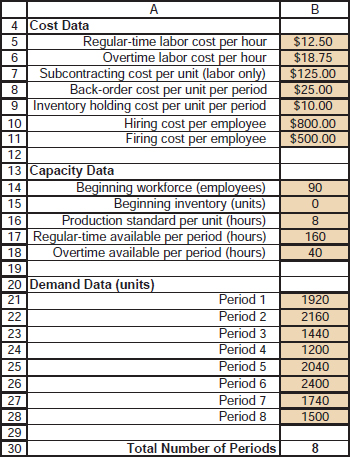

Use the problem data in Table 13-11 for Solved Problems 1–4.

TABLE 13-11 Data for Solved Problems 1–4

• Problem 1: Plan 1: Level Aggregate Plan Using Inventories and Back Orders

Develop a level aggregate plan using inventories and back orders. Test and evaluate the plan.

• Before You Begin:

Remember that a level strategy can use inventories and back orders to satisfy fluctuations in demand. You need to determine the aggregate production rate needed and then the size of the workforce needed to produce that rate. Follow the steps below.

• Solution

Step 1 Choose the kind of aggregate plan. In this case we use a level aggregate plan.

Step 2 Calculate the aggregate production rate. We use the level option to calculate the average period demand rate. First, we add up the period demands and divide by the number of periods (14,400 units/8 = 1800 units per period); then we find the average production rate needed. If we have a beginning inventory, we subtract it from the total demand figure. If we have a desired ending inventory, we add that to the total demand figure. Otherwise, the 1800 units we calculated earlier is our average demand and subsequently our aggregate production rate.

Step 3 Calculate the number of workers to produce 1800 units per period. Since each employee works 160 hours per period and each unit takes 8 ...

Get Operations Management: An Integrated Approach, 5th Edition now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.